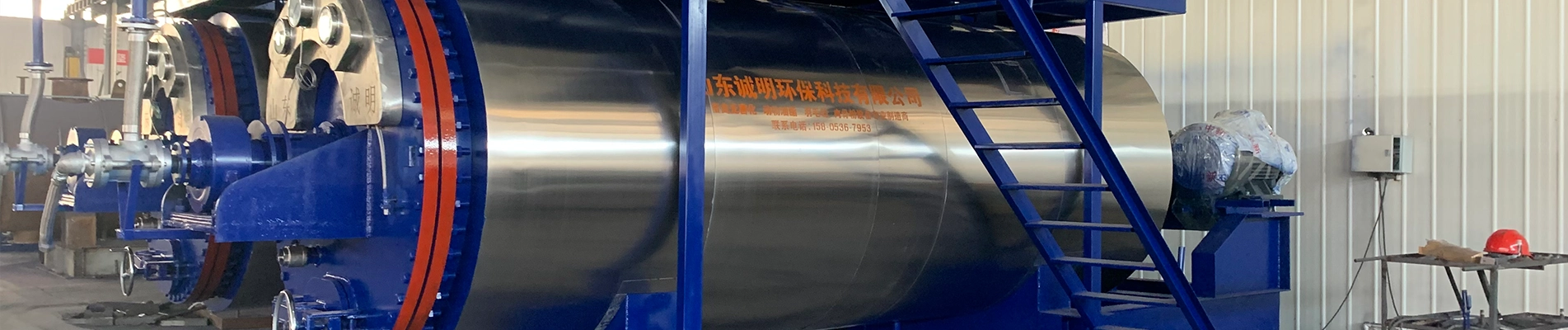

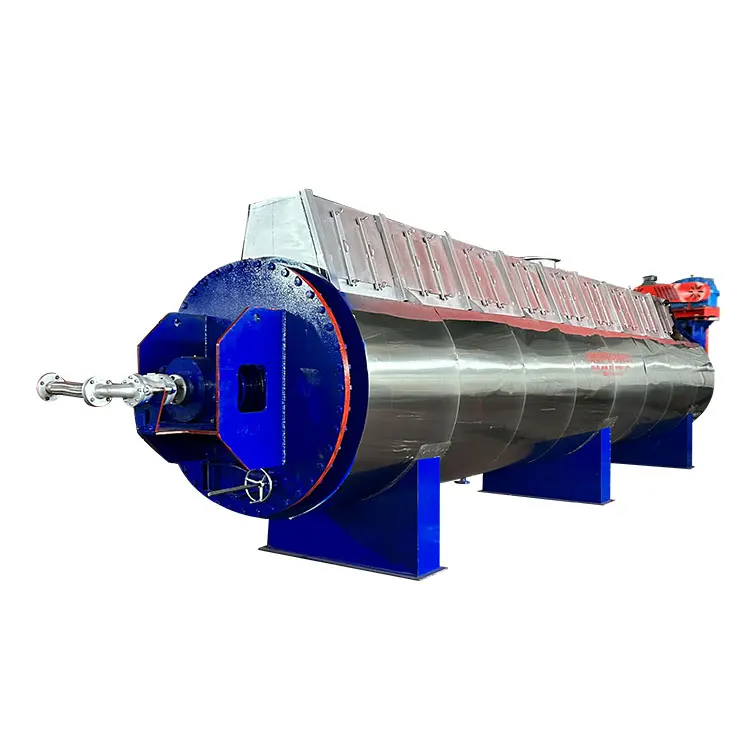

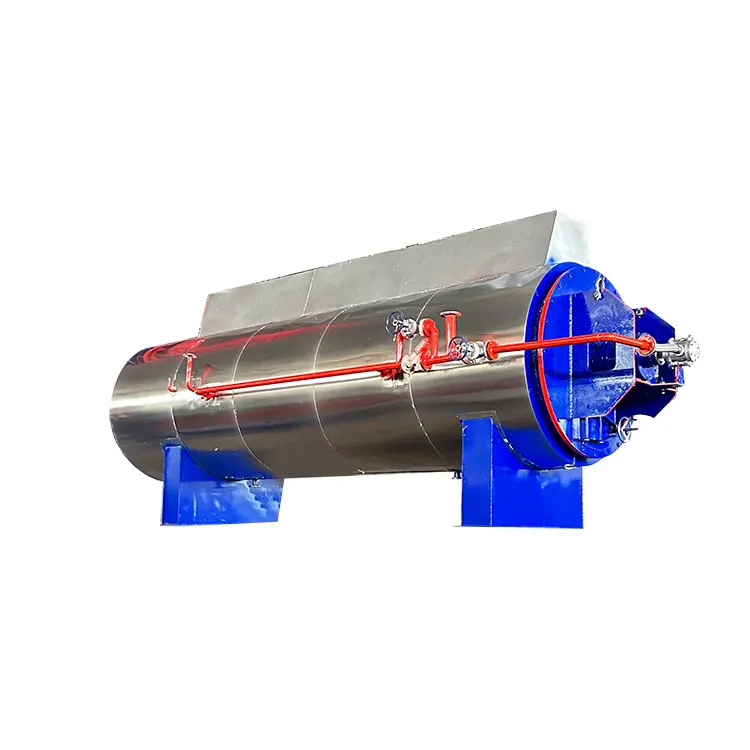

Meat Bone Meal Equipment

Meat and bone meal is a protein feed resource with high nutritional value. It can be used as a source of animal protein in livestock feed and is currently widely used in my country's feed industry.

This production process uses the inedible scraps of animals after slaughter, as well as the residual minced meat, viscera, and miscellaneous bones from meat canning factories and meat processing as raw materials. The product is obtained after high-temperature steaming and sterilization, pressing and defatting, drying, screening, crushing, and cooling.

In the production process of meat and bone meal, meat bone meal equipment should be used. The raw materials are first sent to the crusher to be crushed into uniform blocks, and then the raw materials are continuously and evenly sent to the steamer by the screw conveyor. After indirect steam heating, the cooked raw materials are directly sent to the press. Under the extrusion of the twin screws, the juice leaks out from the filter and flows into the juice tank. After being heated by the protein water heater, it is sent to the three-phase horizontal centrifuge to achieve solid-liquid-liquid separation. The solid phase meat residue is reused in the meat and bone meal processing and drying process, and the oil is obtained by high-speed centrifugal separation or natural precipitation through a disc separator or a sedimentation tank to obtain a purer oil product. The oil can be shipped as a crude oil product. The protein water separated by the three-phase horizontal centrifuge and the disc separator is rich in water-soluble protein, so it is pumped back to the dryer for drying, which increases the yield and protein content of meat and bone meal. The pressed cake with a moisture content of about 50% is sent to the dryer by a screw conveyor, where excess moisture is evaporated. It is first screened out by a powder sifter to remove impurities such as meat and bones, and then sent to a grinder for crushing to obtain meat and bone meal with uniform particle size. Finally, it is sent to a wind and water cooling machine for cooling. After the meat and bone meal has been cooled to room temperature, it can be shipped out after final weighing and packaging.