Email Us

What is the function of feather meal equipment?

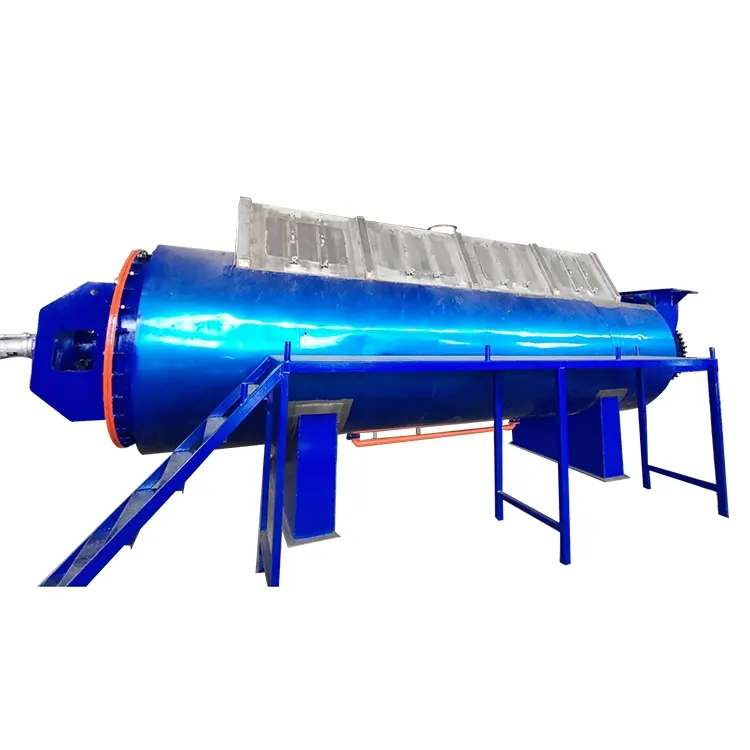

As a key equipment for livestock and poultry waste treatment, feather meal equipment converts feathers that were originally difficult to use into high-value protein raw materials through a systematic processing process, achieving a win-win situation of resource recycling and environmental protection.

The core function lies in the efficient processing and conversion of feathers. The equipment first crushes the collected poultry feathers into 3-5 mm short fibers through a crushing system to solve the problem that feather keratin is difficult to degrade. Then it enters the high-temperature and high-pressure hydrolysis device, and at 140-180℃ and 0.5-0.8MPa pressure, it destroys the keratin structure of the feather fiber, breaks the protein molecular chain, and converts it into easily absorbed small molecule protein. This process also achieves sterilization and disinfection, and removes pathogenic microorganisms.

The drying and milling process improves the applicability of the product. The hydrolyzed feather pulp is dehydrated by a drum dryer, and the moisture content is reduced to less than 10%, and then it is made into a powder product of 80-100 mesh through a grinding system. The whole set of equipment can adjust parameters according to demand to produce feather meal with a crude protein content of more than 80%, meeting the feed addition standards for different breeding scenarios.

The environmental protection function is irreplaceable. Traditional feather incineration or landfill will produce odor and pollution. The feather meal equipment reduces exhaust gas emissions through closed treatment, and the wastewater generated during the processing can be recycled after treatment to achieve zero pollutant emissions. It is estimated that a set of medium-sized equipment can process up to 300 tons of feathers per year, reducing the pollution of about 50 tons of nitrogen to the environment.

Extended functions help upgrade the industrial chain. The produced feather meal can be added to poultry, livestock and aquatic feed as a substitute for fish meal to reduce breeding costs; in the production of organic fertilizers, feather meal becomes a high-quality organic nitrogen source after fermentation to improve soil fertility. Some equipment can also be compatible with the treatment of waste containing keratin such as hoof horns and hair to expand application scenarios.

At present, feather meal equipment has become a standard feature of breeding enterprises and waste treatment plants. Its functions cover the entire chain of "treatment - transformation - utilization", which not only solves environmental problems, but also creates economic value and promotes the transformation of the livestock industry to a green recycling model.

- What Makes a Machine Making Feather Powder Essential for Modern Recycling Industries?

- Why Should You Choose Animal Harmless Treatment Equipment for Your Facility?

- Why Is a Grain Sterilization Tank Essential for Modern Food Processing?

- What is Animal Oil Refining Equipment and Why is it Essential?

- Why Choose a Harmless Treatment Humidifier for Your Air Quality Needs?

- What Exactly is Chicken Feather Powder Equipment and How Can It Boost Your Profits?

Contact Us

Shunwang Avenue, Zhucheng City, Shandong Province, China

Copyright © 2024 Shandong Chengming Environmental Protection Technology Co., Ltd. All Rights Reserved.