Email Us

Harmless Treatment Humidifier

- View as

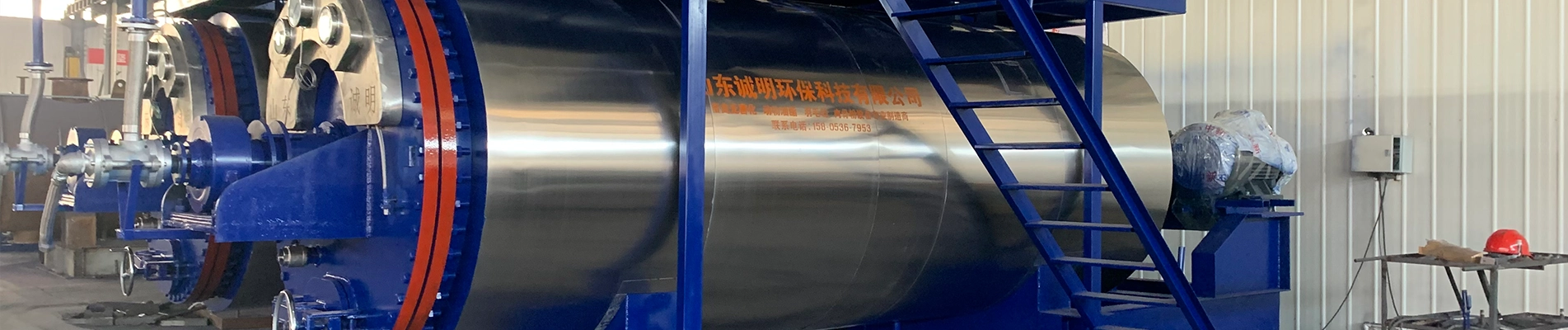

Slaughterhouse Waste Harmless Treatment Equipment

Our slaughterhouse waste harmless treatment equipment complies with the requirements of GB/T16548-1996 "Procedure for the harmless treatment of diseased meat carcasses and their products of livestock and poultry", and can completely kill the pathogenic microorganisms of 19 major animal diseases determined by the state, and can harmlessly treat the lesions of 46 animal diseases such as anthrax, foot-and-mouth disease, swine fever, Newcastle disease, etc., as well as the waste and glands of cuttings. It will play a positive role in eliminating and controlling major animal diseases, comprehensively improving the quality of animal epidemic prevention, preventing diseased pig products from entering the market, ensuring the quality and safety of marketed pig products, ensuring the safety of meat food, and protecting the health of the people.

Farm Harmless Treatment Equipment

Shandong Chengming Environmental Protection is a company dedicated to the research, design, production, and sales of comprehensive livestock farm harmless treatment equipment. Located at No.10616 Shunwang Avenue, Zhucheng City, Shandong Province, the company covers an area of 20,000 square meters, with a factory occupying 8,000 square meters.

Slaughterhouse Humidifier

The treatment method of the slaughterhouse humidifier is to use high-temperature and high-pressure saturated steam to directly contact the livestock and poultry carcasses, place the livestock and poultry carcasses in a high-temperature and high-pressure environment, melt the fat, and hydrolyze the protein by wet heat. At the same time, with the help of high temperature and high pressure, the pathogens carried in the livestock and poultry carcasses are killed.

Harmless Treatment Humidifier for Farms

Shandong Chengming Environmental Protection is a company dedicated to the research, design, production, and sales of complete sets of harmless treatment humidifier for farms. Located at No.10616 Shunwang Avenue, Zhucheng City, Shandong Province, the company covers an area of 20,000 square meters, with a factory occupying 8,000 square meters.

We are looking forward to your buy Harmless Treatment Humidifier from our company made in China - Chengming Environmental Protection. Our factory is a Harmless Treatment Humidifier manufacturer and supplier in China. You are welcome to buy our high quality products.

Contact Us

Shunwang Avenue, Zhucheng City, Shandong Province, China

Copyright © 2024 Shandong Chengming Environmental Protection Technology Co., Ltd. All Rights Reserved.