Email Us

How Can the New Generation Livestock Carcass Crusher Overcome Processing Challenges?

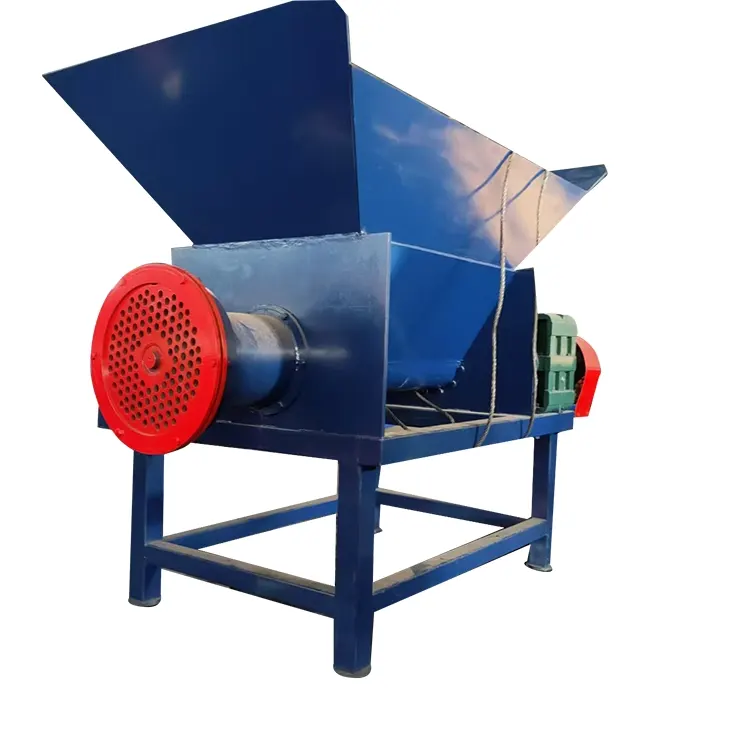

In the livestock processing industry, efficient carcass crushing is essential for maintaining smooth operations. However, traditional livestock carcass crushers often struggle with several issues, such as incomplete shredding of animal skins and intestines, blockages in conveyor systems, and uneven crushing of bones and meat. These problems not only slow down processing but also affect the quality of the final output. To address these challenges, our company has developed a new generation of livestock carcass crushers with advanced features that significantly improve efficiency and reliability.

Overcoming the Limitations of Traditional Crushers

Traditional carcass crushers mainly function as "tearing" machines, which results in several drawbacks:

- Inefficient Crushing: Animal skins and intestines are not fully shredded, leading to material entanglement.

- Frequent Blockages: The incomplete breakdown of materials causes conveyor blockages, disrupting the workflow.

- Uneven Processing: Inconsistent crushing of bones and meat impacts downstream operations, especially when materials enter the oil press.

- Extended Processing Time: Inefficiencies in the crushing process slow down production and increase energy consumption.

Advancements in the New Generation Livestock Carcass Crusher

Through continuous improvement, our company has developed a livestock carcass crusher that eliminates these inefficiencies. The upgraded machine offers:

- Smaller and Uniform Crushed Particles: Ensuring optimal material consistency for further processing.

- Complete Shredding of Animal Skins and Intestines: Preventing entanglement and reducing blockages in material transportation.

- Enhanced Processing Speed: Shorter processing time leads to increased efficiency and productivity.

- Seamless Integration with Oil Press Machines: Properly crushed materials enter the oil press smoothly, ensuring uninterrupted production.

- Energy Efficiency: The new design minimizes power consumption, making it both cost-effective and environmentally friendly.

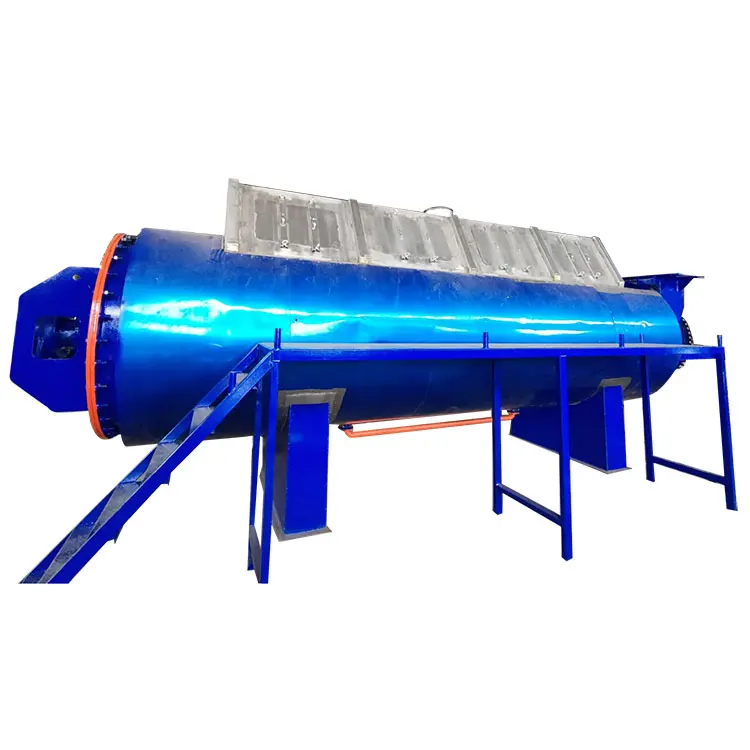

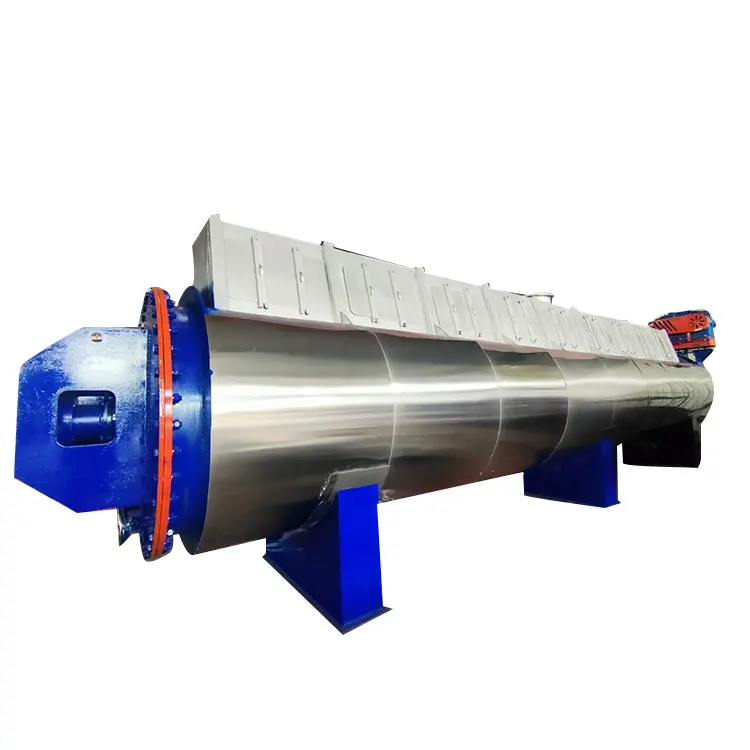

Improving Productivity and Reducing Operational Costs

By solving the major pain points of traditional carcass crushers, the new-generation machine significantly improves workflow efficiency. With reduced downtime, lower energy consumption, and optimized material output, businesses can enhance productivity while cutting operational costs.

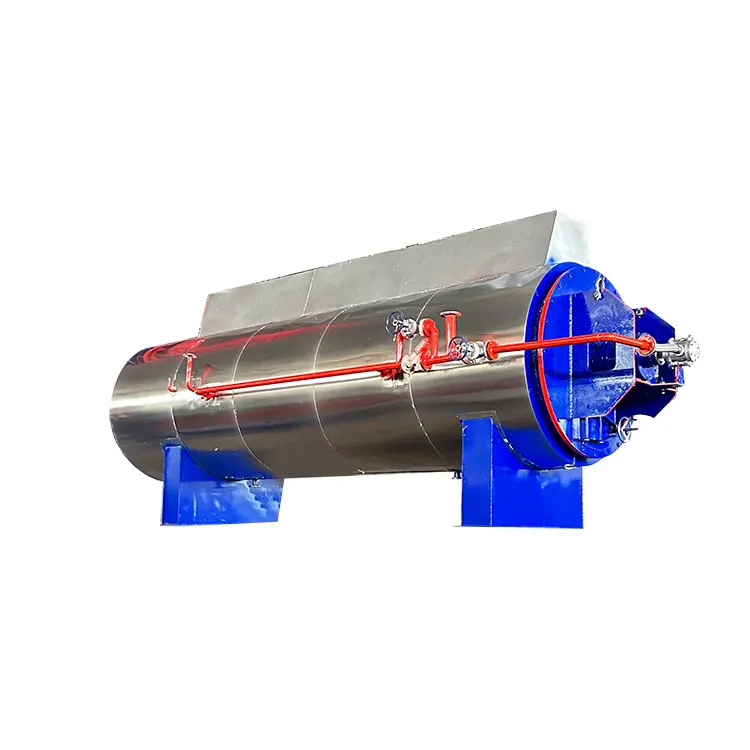

The development of the new-generation livestock carcass crusher marks a significant step forward in animal by-product processing. With its advanced shredding capabilities, blockage-free material transport, and improved energy efficiency, this machine ensures a smoother and more efficient production process. As the industry evolves, investing in innovative equipment like this will be key to maintaining high standards of efficiency and profitability.

Shandong Chengming Environmental Protection Technology Co., Ltd. was established in 2018 and is located in Zhucheng, Shandong. The main products include complete sets of environmental protection equipment such as harmless treatment equipment for dead animals, waste gas treatment equipment, and so on. Explore our full range of products on our website at https://www.sdcmep.com/. For any inquiries, please reach out to us at 447353695@qq.com.

- Why Should You Choose Animal Harmless Treatment Equipment for Your Facility?

- Why Is a Grain Sterilization Tank Essential for Modern Food Processing?

- What is Animal Oil Refining Equipment and Why is it Essential?

- Why Choose a Harmless Treatment Humidifier for Your Air Quality Needs?

- What Exactly is Chicken Feather Powder Equipment and How Can It Boost Your Profits?

- How is this feather meal production line innovative?

Contact Us

Shunwang Avenue, Zhucheng City, Shandong Province, China

Copyright © 2024 Shandong Chengming Environmental Protection Technology Co., Ltd. All Rights Reserved.