Email Us

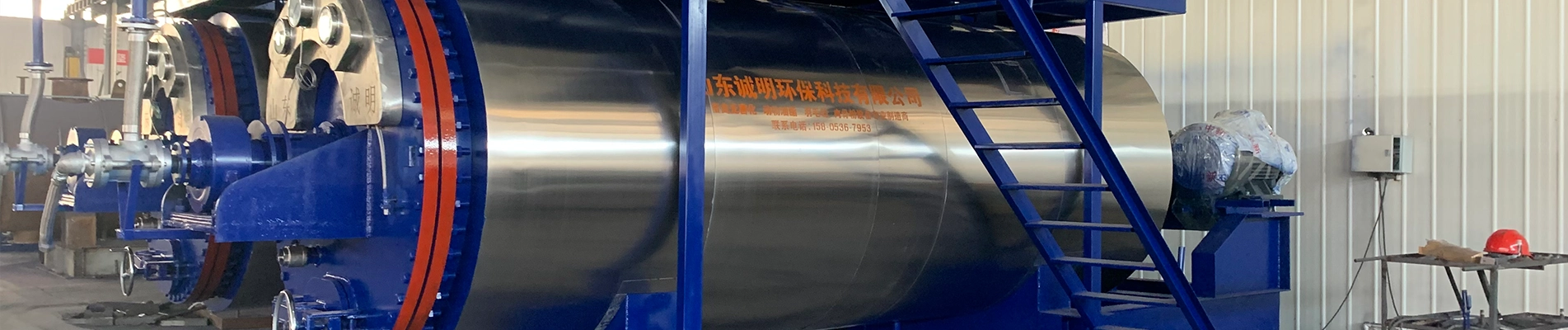

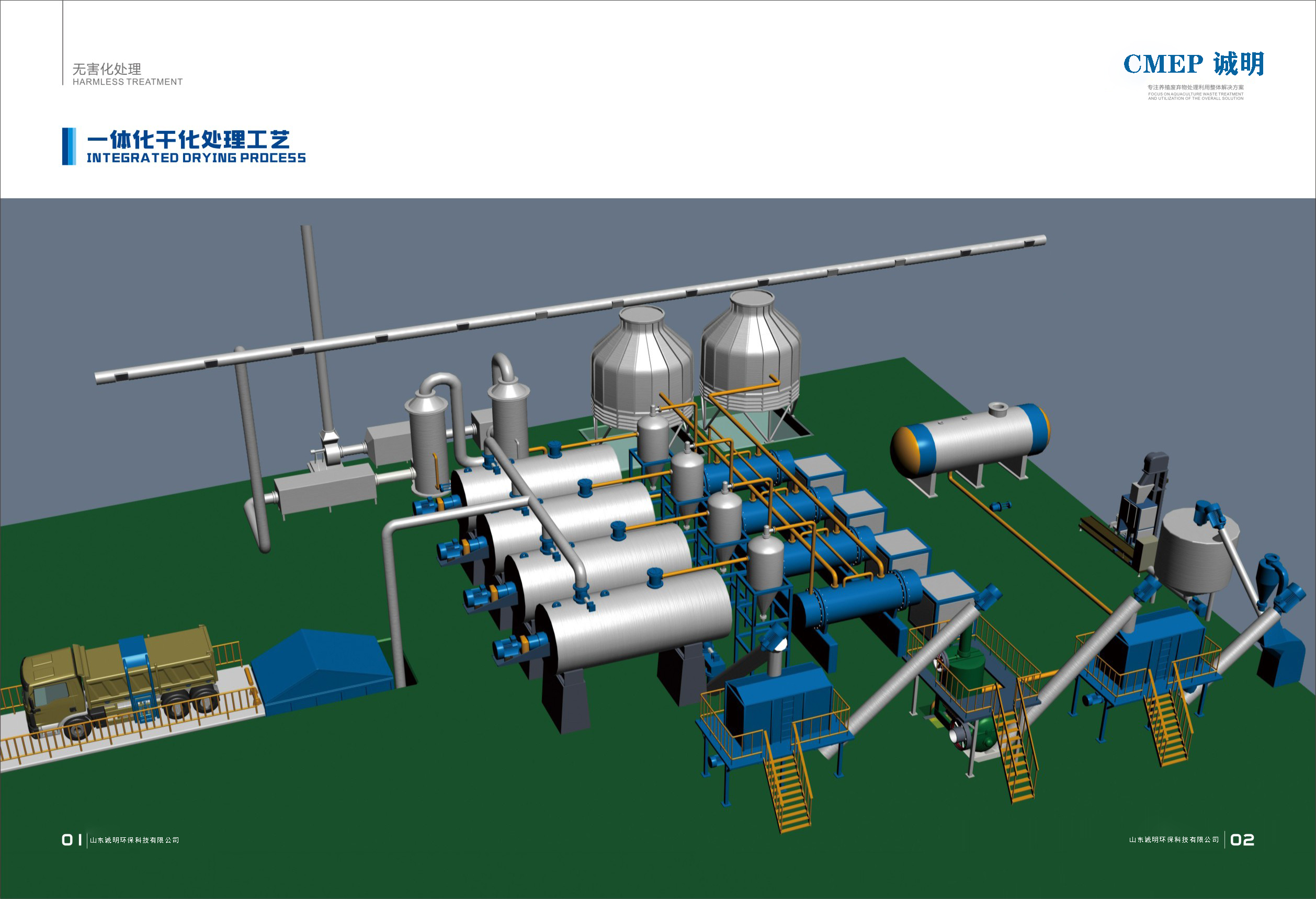

Hydrolyzed Feather Powder Processing Equipment

Hydrolyzed feather powder processing equipment is a key equipment for harmless treatment of slaughter waste. Its purpose is to treat the feathers of dead animals through high temperature and high pressure to achieve the purpose of maturation and sterilization.

Parameters:

|

Model |

CMJ-5 |

|

Tank size (mm) |

φ1600/1800×4500 |

|

Effective volume (m³) |

9.6 |

|

Design pressure (Mpa) |

0.45/0.65 |

|

Working pressure (Mpa) |

0.4/0.6 |

|

Design temperature (℃) |

160/190 |

|

Working temperature (℃) |

150/180 |

|

Processing capacity (T) |

8.0 |

|

Power (kW) |

45 |

Performance characteristics:

In the aspect of enhanced heat exchange, the equipment incorporates a double-layer jacketed shell configuration. Steam is employed as the heat transfer medium within this structure. This design serves to optimize heat exchange efficiency to the fullest extent. It ensures that feathers come into uniform contact with high-temperature environments (reaching up to 120℃). Through this process, thorough ripening and sterilization effects are achieved. Meanwhile, the design effectively eliminates local cold spots. This elimination guarantees the stability and uniformity of product quality.

With regard to durable structure, the stirring teeth are constructed from Q345R alloy steel. This material is characterized by superior tensile strength and wear resistance. It is capable of withstanding continuous abrasion during the feather processing procedure. This capability helps to reduce the frequency of maintenance. The equipment is also equipped with seamless steel shafts and integral steel brackets. These components ensure structural stability even under maximum load conditions (5 tons per batch).

Safety and reliability are realized via the integration of independent exhaust mechanisms. They are also achieved through the inclusion of pressure gauges with automatic overpressure release functionality. Additionally, impact block-type feeding and discharging systems are configured. These components work together to substantially mitigate the risks of leakage, pressure accumulation, and material splashing. They enable the equipment to meet global safety standards. Furthermore, they protect the safety of operators. They also contribute to extending the service life of the equipment.

The energy-saving and water-saving design is manifested in the incorporation of an automatic condensate recovery system. This system is capable of efficiently reclaiming steam condensate. This reclamation markedly decreases water consumption. It also reduces boiler fuel consumption. In addition, energy consumption is optimized through the application of hydraulic couplings and gear ring transmission devices. This optimization results in a reduction of operating costs by 15%-20%.

In terms of intelligent automation, the equipment encompasses functionalities including real-time temperature and pressure monitoring. It also includes motor-driven weight measurement capabilities. These functionalities serve to minimize manual involvement. Operators are able to set parameters through a human-machine interaction control panel. This action ensures processing accuracy. It also guarantees product consistency across different production batches.

Corrosion resistance is ascribed to the employment of a stainless steel-clad insulation layer configuration. This configuration provides protective coverage for internal components. It enables the equipment to withstand erosion from humid environments and chemical substances. As a result, the equipment is suitable for long-term stable operation in humid settings such as slaughterhouses and poultry farms.

Key Specifications & Technical Parameters

Shandong Chengming’s hydrolyzed feather powder processing equipment is engineered for precision, efficiency, and durability. Below is a detailed breakdown of its core components, materials, and performance metrics:

|

Component |

Material/Design |

Key Function |

Performance Advantages |

|

Outer Shell |

Double-layer jacket (steam-filled) |

Enhances heat exchange efficiency during high-temperature treatment. |

Increases thermal conductivity by 30% compared to single-layer designs; ensures uniform heating. |

|

Intermediate Shaft |

Seamless steel pipe |

Supports stirring mechanism and maintains structural integrity under pressure. |

Resists deformation at high temperatures (up to 120°C) and pressures. |

|

Stirring Teeth |

Q345R alloy steel |

Mixes and agitates feathers for consistent hydrolysis. |

50% higher wear resistance than standard steel; extends service life by 3–5 years. |

|

Support Structure |

Integral steel frame |

Provides stability and flexibility in installation. |

Allows easy repositioning; withstands heavy loads (up to 5T/batch). |

|

Inlet/Outlet System |

Collision block design |

Facilitates smooth material transfer; prevents leakage. |

Reduces manual operation time by 20%; minimizes material spray during loading/unloading. |

|

Exhaust Port |

Separate, pressure-controlled |

Releases excess steam safely. |

Prevents pressure buildup; enhances operational safety. |

|

Drainage System |

Automatic condensate recovery |

Recycles steam condensate back to the boiler. |

Reduces water consumption by 40%; lowers energy costs. |

|

Temperature Monitoring |

Electric thermocouple (inner layer) |

Measures real-time temperature of maturing material. |

Accuracy within ±1°C; ensures optimal hydrolysis conditions. |

|

Pressure Gauge |

Jacket-layer mounted |

Monitors steam pressure; triggers automatic overpressure release. |

Prevents equipment damage; complies with safety standards. |

|

Material Weight Measurement |

Motor current sensor |

Calculates material weight in the tank via instantaneous current readings. |

Eliminates manual weighing; ensures precise batch control. |

|

Transmission System |

Hydraulic coupling + gear ring |

Reduces impact during startup/shutdown; optimizes energy use. |

Cuts energy consumption by 15%; minimizes wear during power outages or jams. |

|

Insulation Layer |

Stainless steel cladding |

Insulates equipment; resists corrosion. |

Maintains thermal efficiency; enhances durability in humid environments. |

-

Address

Shunwang Avenue, Zhucheng City, Shandong Province, China

-

Tel

-

E-mail

Contact Us

Shunwang Avenue, Zhucheng City, Shandong Province, China

Copyright © 2024 Shandong Chengming Environmental Protection Technology Co., Ltd. All Rights Reserved.