Email Us

What is the extraction process of animal oil refining equipment?

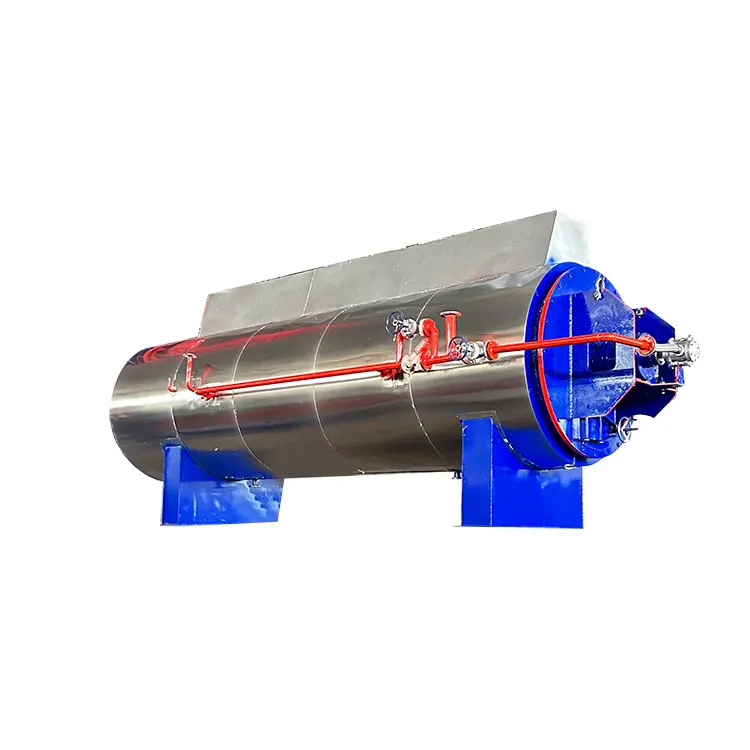

Animal oil refining equipment is a key equipment in the oil processing industry. Its extraction process is directly related to whether high-quality, pure and impurity-free refined oil can be obtained. Let's talk about this process in detail.

Raw material pretreatment is the first step of the entire refining process. The core is to remove impurities and foreign matter in the oil and fat, laying the foundation for subsequent steps. First, make a preliminary screening of the raw materials to pick out impurities such as stones and metals; then clean the raw oil and fat to remove surface stains and moisture; finally, break the raw materials into small particles, which can increase the surface area and allow the raw materials and refining agents to contact and react better during subsequent refining.

Degumming and deacidification are very important links in the refining process. Degumming mainly uses the hydrophilicity of colloid substances such as phospholipids to precipitate and separate the colloid substances from the oil and fat by adding water, heating and stirring. Doing so can reduce the colloid in the oil and fat, making the oil and fat more transparent and more stable. Deacidification is to add alkaline substances such as sodium hydroxide to react with the free fatty acids in the oil to generate soap stock that is easy to separate, thereby reducing the acid value of the oil and ensuring that the acid value of the oil meets the standard.

After degumming and deacidification, the pigments and odors in the oil must be further processed. Decolorization generally involves adding adsorbents such as white clay to remove the pigments through the adsorption effect of the adsorbent, making the color and appearance of the oil better. Deodorization is to use the characteristics of odor substances that are easy to volatilize under high temperature and high vacuum environment, separate these odor substances through steam distillation, and improve the smell and flavor of the oil.

Winterization and filtration can make the oil purer. Winterization is to control the temperature so that high-melting-point substances such as wax in the oil can be crystallized and separated, which can improve the transparency and stability of the oil. Specifically, it is to cool the oil to a certain temperature, let the high-melting-point substances slowly crystallize, and then separate the crystals and oil by filtering to obtain purer oil.

The last step is the storage and packaging of refined oil. After the above steps, the refined oil should be stored in a clean, dry and dark place to prevent oxidation and deterioration. The packaging uses food-grade materials such as stainless steel barrels and food-grade plastic barrels to ensure that the refined oil is clean and safe during storage and transportation.

The extraction process of animal oil refining equipment is complex and delicate. From raw material pretreatment to degumming and deacidification, decolorization and deodorization, to winterization filtration, storage and packaging, each link must strictly control the process parameters and operating conditions to ensure the final refined oil is of good quality and high purity. With the development of science and technology and process improvement, the production efficiency and product quality of animal oil refining equipment will continue to improve, adding strength to the development of the oil processing industry.

- What Makes a Machine Making Feather Powder Essential for Modern Recycling Industries?

- Why Should You Choose Animal Harmless Treatment Equipment for Your Facility?

- Why Is a Grain Sterilization Tank Essential for Modern Food Processing?

- What is Animal Oil Refining Equipment and Why is it Essential?

- Why Choose a Harmless Treatment Humidifier for Your Air Quality Needs?

- What Exactly is Chicken Feather Powder Equipment and How Can It Boost Your Profits?

Contact Us

Shunwang Avenue, Zhucheng City, Shandong Province, China

Copyright © 2024 Shandong Chengming Environmental Protection Technology Co., Ltd. All Rights Reserved.