Email Us

Analysis of incineration equipment, chemical treatment equipment and fermentation equipment in animal harmless treatment equipment.

Incineration equipment mainly converts animal carcasses and waste into ashes and harmless gases through high-temperature combustion. Its working principle is to use the high temperature generated by fuel combustion to rapidly decompose the organic matter in animal carcasses. In terms of performance parameters, the processing capacity depends on the scale and design of the incinerator and can generally handle a large number of animal carcasses. Energy consumption is relatively high, mainly due to fuel consumption. The floor area is relatively large, and a special incineration facility needs to be constructed. The advantage is that the processing speed is fast and pathogens can be completely eliminated, reducing the risk of epidemic transmission. However, the limitations are also obvious. For example, harmful gases such as dioxins will be generated during the combustion process, and advanced waste gas treatment equipment is required; the cost is high, including equipment purchase, operation and maintenance costs.

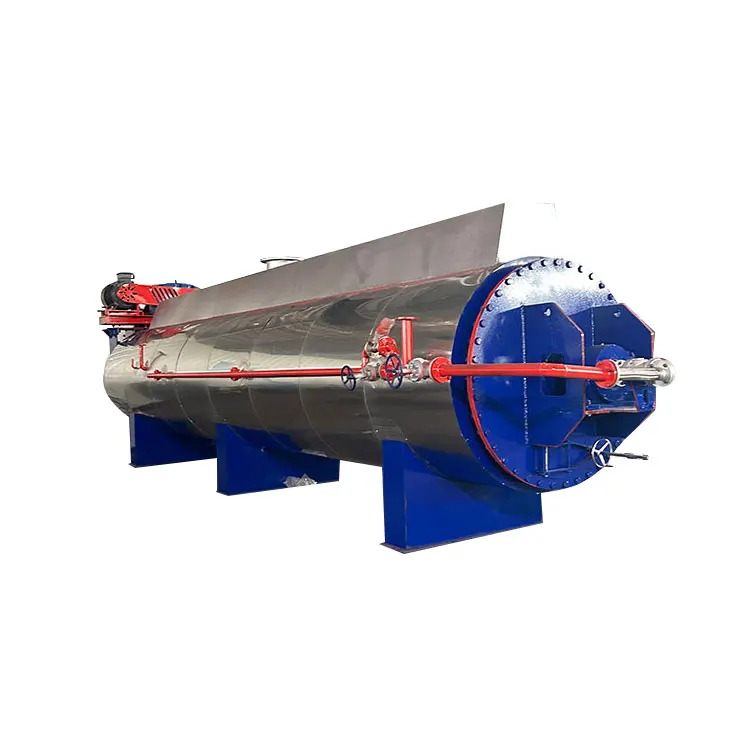

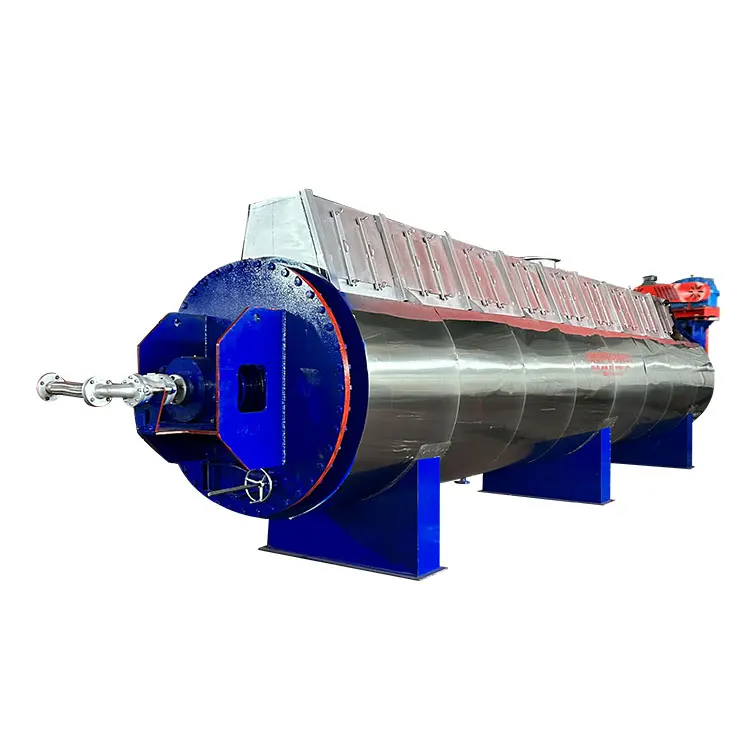

Chemical treatment equipment decomposes animal carcasses into products such as grease and bone meal through high-temperature and high-pressure treatment. The working principle is that under certain temperature and pressure, the organic matter such as protein in animal carcasses undergoes hydrolysis and pyrolysis reactions. In terms of performance parameters, the processing capacity varies depending on the equipment model. Energy consumption is mainly steam or electricity. The floor area is moderate. Its advantage is that it can realize resource recycling. For example, products with economic value such as grease and bone meal can be produced. The limitation is that waste water and waste gas may be generated during the processing process and need to be treated; the requirements for the sealing and pressure resistance of the equipment are relatively high.

Fermentation equipment uses the fermentation of microorganisms to decompose animal carcasses into organic fertilizers. The working principle is to mix animal carcasses with specific microbial strains. Under suitable temperature and humidity conditions, microorganisms grow and reproduce and decompose the organic matter in animal carcasses. In terms of performance parameters, the processing capacity is relatively small, and energy consumption is mainly to maintain the temperature and humidity required for fermentation. The floor area is small. The advantage is that it is environmentally friendly and does not generate harmful gases and waste water; the cost is low. The limitation is that the processing time is relatively long, and the environmental conditions are relatively high. If the temperature, humidity and other controls are improper, it may affect the fermentation effect.

Contact Us

Shunwang Avenue, Zhucheng City, Shandong Province, China

Copyright © 2024 Shandong Chengming Environmental Protection Technology Co., Ltd. All Rights Reserved.