Email Us

What is the operating procedure of the harmless treatment humidifier?

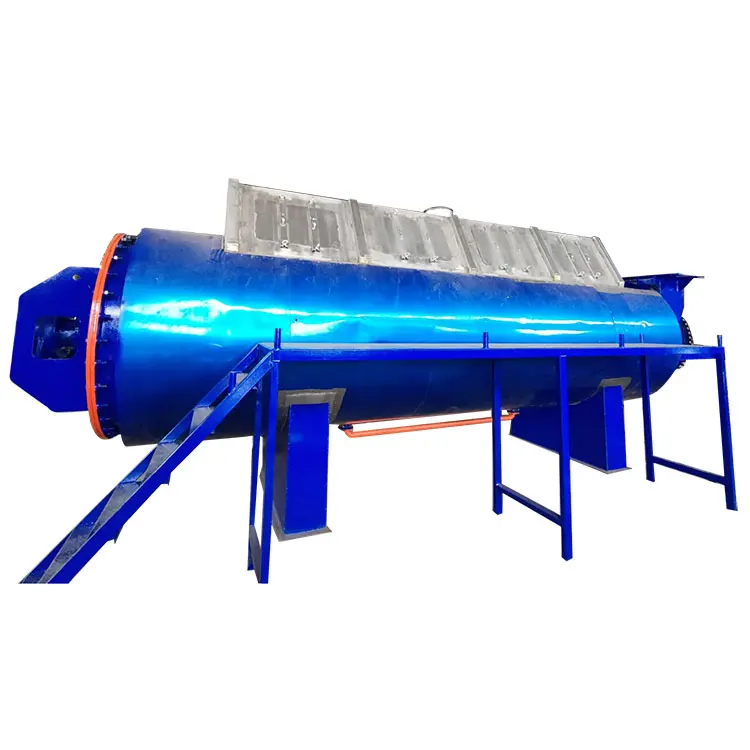

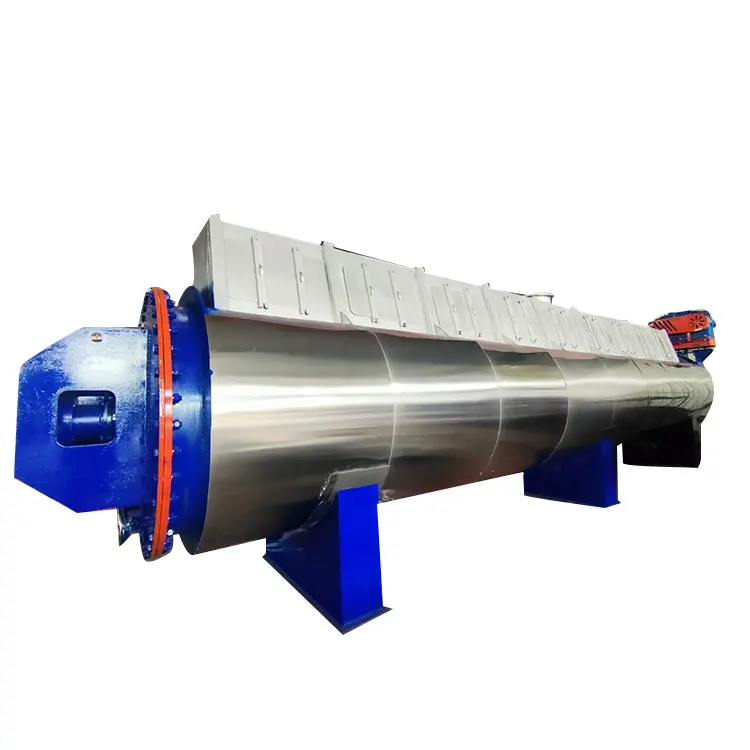

As a key equipment for livestock and poultry waste treatment, the harmless treatment humidifier has a standardized operating procedure that directly affects the sterilization effect and resource recovery efficiency, and five core steps must be strictly followed.

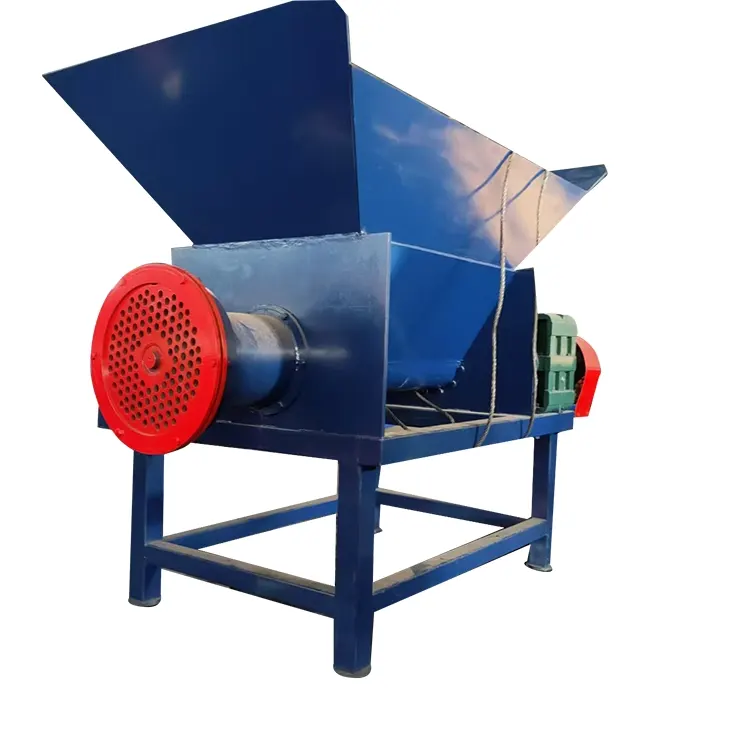

The first is material pretreatment and loading. Transport sick pigs and related products to the harmless treatment room, and directly load them into special medicine baskets after sorting to ensure that the materials are evenly placed to avoid excessive accumulation affecting steam circulation. Then place the medicine basket on the cart and smoothly send it into the humidifier along the track. After confirming that it is in place, close the tank door and check whether the sealing ring is tight to prevent steam leakage during operation.

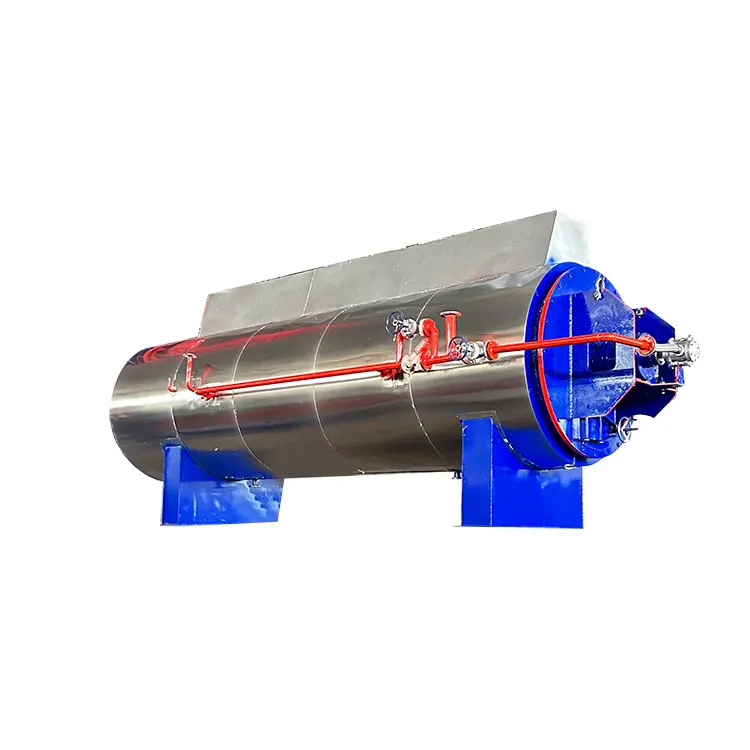

The second is parameter setting and start-up operation. According to the type and quantity of materials, set the temperature and pressure parameters in the control system. Usually the temperature is controlled at 160-190℃ and the pressure is maintained at 0.6Mpa. After the parameters are confirmed to be correct, start the equipment. After the parameters are confirmed to be correct, start the equipment. The high temperature and high pressure environment will complete the sterilization of the materials within the predetermined time, completely killing pathogens and harmful microorganisms.

During the treatment process, the operating status of the equipment needs to be monitored in real time, and the pressure gauge and temperature display must be observed to ensure that all parameters are stable within the set range. If abnormal fluctuations occur, the system will automatically alarm. At this time, the operation should be suspended, and the cause should be checked. It should be restarted after the fault is eliminated.

After the treatment is completed, it enters the resource recovery stage. First, the oil-water mixture produced in the process is transported to the oil-water separation equipment through a special pump. After separation, high-purity oil and fat can be obtained to achieve resource recycling. Then open the tank door and slowly pull out the medicine basket along the track to prevent the residue from scattering.

Finally, the residue is treated and the equipment is reset. The residue in the medicine basket is transported to the biogas tank for fermentation or treated uniformly with animal feces to realize waste resource utilization. After the operation is completed, clean up the remaining debris inside the equipment, turn off the power and steam valve, and prepare for the next operation.

Standardizing the implementation of this process when using a harmless treatment humidifier can not only ensure that the materials are thoroughly sterilized, but also improve resource recovery efficiency, providing reliable guarantees for environmentally friendly treatment in the breeding industry.

- Why Should You Choose Animal Harmless Treatment Equipment for Your Facility?

- Why Is a Grain Sterilization Tank Essential for Modern Food Processing?

- What is Animal Oil Refining Equipment and Why is it Essential?

- Why Choose a Harmless Treatment Humidifier for Your Air Quality Needs?

- What Exactly is Chicken Feather Powder Equipment and How Can It Boost Your Profits?

- How is this feather meal production line innovative?

Contact Us

Shunwang Avenue, Zhucheng City, Shandong Province, China

Copyright © 2024 Shandong Chengming Environmental Protection Technology Co., Ltd. All Rights Reserved.