Email Us

Meat Bone Meal Processing Equipment

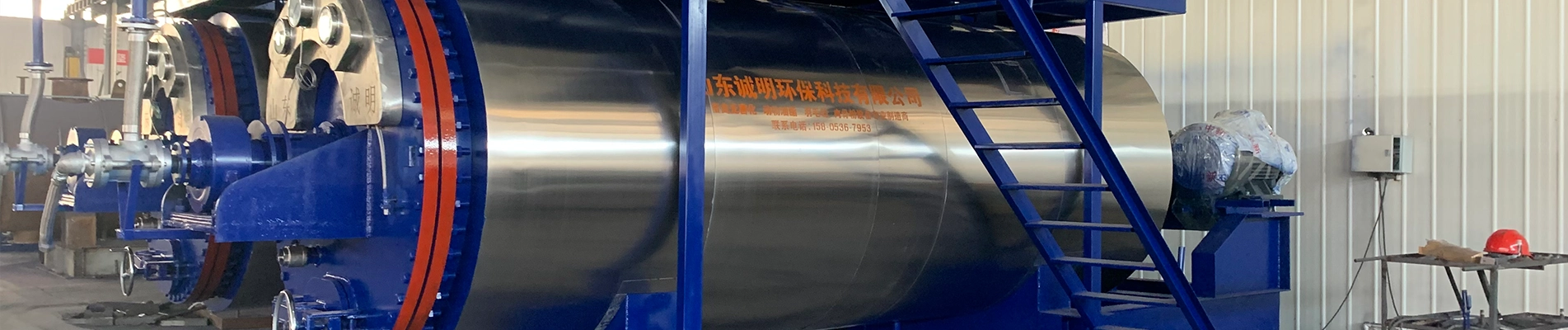

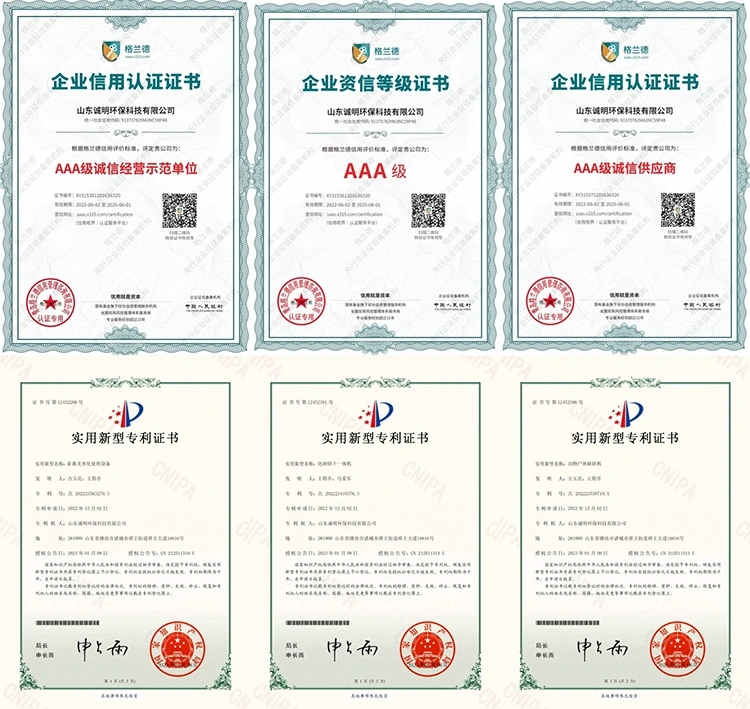

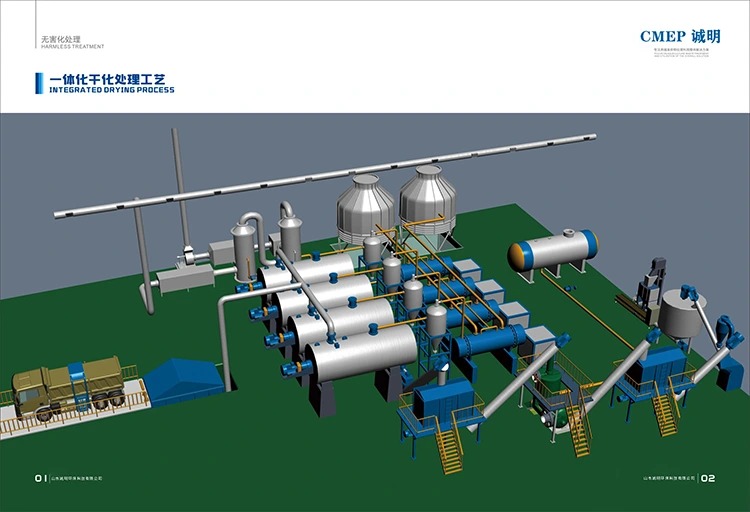

Shandong Chengming Environmental Protection is a company dedicated to the research, design, production, and sales of complete meat bone powder equipment. Located at No.10616 Shunwang Avenue, Zhucheng City, Shandong Province, the company covers an area of 20,000 square meters, with its factory occupying 8,000 square meters. It focuses on the research and development of harmless processing production. The company has obtained——ISO9001 Quality Management System certification, ISO14001 Environmental Management System certification, and OHSAS18001 Occupational Health and Safety Management System certification. Additionally, it holds various manufacturing permits related to its products. Products are manufactured strictly according to design standards. The company is the——national industry standard drafting and customization unit for harmless processing equipment and a member of the China Harmless Processing Equipment Professional Committee.

For many years, we have provided professional equipment and technical services to customers. We mainly produce harmless treatment equipment for livestock and poultry, harmless treatment equipment for farms, harmless treatment equipment for dead animals, feather powder processing equipment, meat and bone meal processing equipment, animal fat refining equipment, wetting machines, feather powder dryers, etc.

Our company produces excellent equipment at a reasonable price. In the process of transaction, we not only provide you with professional pre-sale services, but also have perfect after-sales service to ensure that you get more than you pay for experience. We look forward to becoming your long-term partner in China.

Description of meat bone powder equipment, with three A certificates

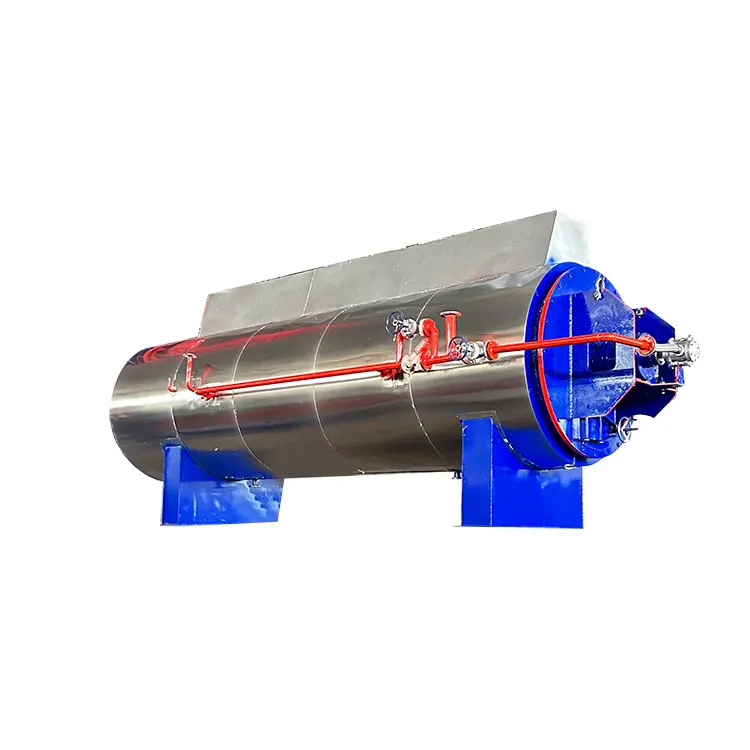

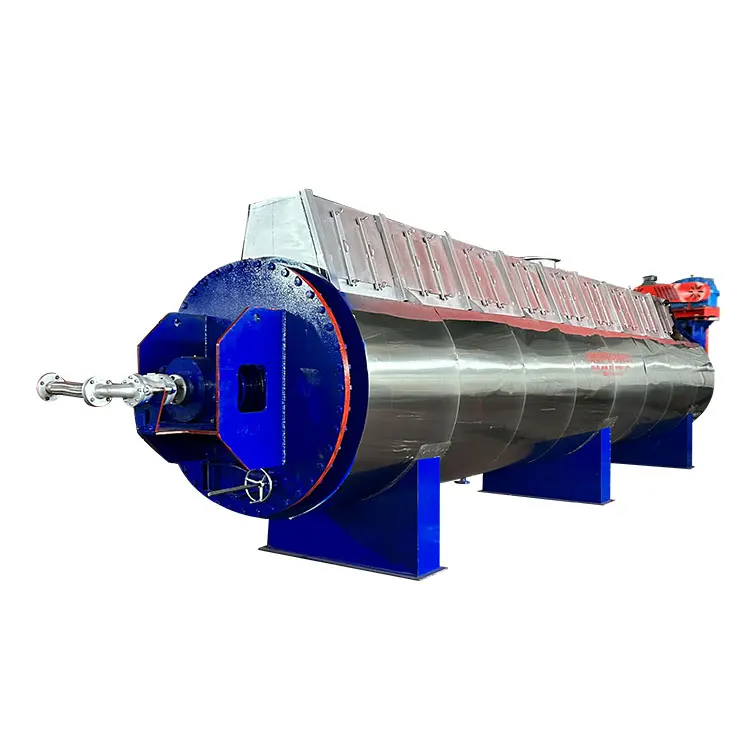

Using high pressure saturated steam, contact with carcass tissue is indirectly, and the pathogen is killed and the moisture inside the material is dried by means of high temperature and high pressure. The dried material is a mixture of meat powder and animal fat, and then the oil and bone powder are separated after the material is pressed, and finally the oil and meat powder are obtained.

corporation charter:

Parameter

|

model |

design temperature (℃) |

Design pressure (MPA) |

handling capacity (t) |

power (W) |

|

CMJ-1 |

160/190 |

0.45/0.65 |

1 |

22 |

|

CMJ-2 |

160/190 |

0.45/0.65 |

2 |

37 |

|

CMJ-3 |

160/190 |

0.45/0.65 |

3 |

37 |

|

CMJ-5 |

160/190 |

0.45/0.65 |

5 |

45 |

process flow

Meat powder equipment is usually composed of several parts, each part works together to achieve the transformation from animal raw materials to meat powder products, the following is a description of the main components and functions:

Raw material processing equipment

Chemical and drying equipment

Oil separation and purification equipment

Pulverizing and packaging equipment

Pulverizer: the meat and bone residue after degreasing is crushed into powder to obtain finished meat and bone powder. For example, the meat and bone powder crusher produced by Dahu Machinery Factory in Hedong District, Linyi City can crush the material to the required particle size 9.

Packaging machine: weigh and package the finished meat powder for storage and transportation, which generally has the characteristics of high degree of automation and accurate measurement.

Waste gas and wastewater treatment equipment

Dust collector: dust removal treatment of waste gas produced in the process of drying, removing solid particles and dust 12.

Crusher: used to crush large raw materials such as animal carcasses and skeletons into smaller pieces for subsequent processing. For example, the animal carcass crusher of Shandong Jinxu Energy Technology Co., Ltd. adopts special tool design to avoid the problem of shaft winding due to the complex characteristics of animal carcass tissue.

Conveying equipment: common ones are screw conveyor, feed pump, etc., which can convey the crushed material to the next process such as the chemical tank, with the advantages of fast speed, small residue and easy cleaning.

Chemical tank: is the core component of meat powder equipment. It uses the principle of high temperature and high pressure to sterilize and process the material, so that the protein is denatured and the fat melts, and at the same time kills pathogenic microorganisms. For example, the chemical tank of HanChuan meat powder drying equipment can treat the material under 121-150℃high temperature and certain pressure for 4.

Drying machine: It is mostly used in low temperature vacuum drying to dry the material after chemical treatment and reduce the water content of the material. For example, Chengming environmental protection meat powder production equipment uses low temperature vacuum drying. After drying for 2 hours, the water content of the material can be reduced to 10%-12%.

Cylinder press: the material after chemical drying is pressed to realize oil residue separation, and meat bone residue and animal fat are obtained. The separated oil has high purity and can be used as raw material for industrial oil 12.

Centrifuge: further purification of the extracted animal fat, through high speed rotation, to separate impurities in the fat, improve the quality of the fat 12.

Spray tower: use spray agent to wash the exhaust gas after dust removal, remove the odor and harmful gases in the exhaust gas

Advantages

Meat powder equipment has many advantages, mainly reflected in the following points:

1. Efficient Processing of Raw Materials: It can centrally process raw materials such as livestock and poultry slaughter waste, dead animals, etc., with large processing volumes, enabling scaled production. For example, large-scale meat meal equipment can handle dozens or even hundreds of tons of raw materials per day, effectively addressing the challenge of waste disposal while avoiding environmental pollution and disease transmission risks caused by random disposal or improper handling.

2. High Quality: Through a series of advanced processes, such as high-temperature cooking, drying, and grinding, the raw materials can be effectively sterilized to eliminate bacteria, viruses, and parasites. The meat meal produced is of stable quality and rich in nutrients. It has a high protein content, typically around 50% -60%, and also contains various minerals and vitamins, making it an excellent animal protein feed ingredient.

3. Resource Recycling: The meat and bone meal equipment converts discarded livestock bones and meat scraps into valuable products, achieving resource recycling. This not only reduces environmental pressure but also provides a crucial raw material source for the feed industry, helping to decrease reliance on imported fish meal and other protein sources. It offers significant economic and social benefits.

4. Automation of Operations: Modern meatball equipment typically employs automated control systems, enabling precise control over the production process. This reduces human operational errors and enhances both production efficiency and product quality stability. Operators only need to set parameters on the control panel, after which the equipment runs automatically according to the preset program, completing a series of processes including raw material conveyance, steaming, drying, grinding, and packaging. This significantly reduces labor costs and work intensity.

5. Good environmental performance: Equipped with advanced environmental protection facilities, such as exhaust gas treatment systems and wastewater treatment systems. During production, the generated exhaust gases are purified to meet emission standards, reducing atmospheric pollution; production wastewater is treated to achieve water resource recycling or compliance with discharge standards, meeting environmental requirements and contributing to sustainable corporate development.

6. Widespread Application: Meat and bone meal, as an excellent protein feed ingredient, can be widely used in livestock and poultry farming, aquaculture, and other fields. Adding an appropriate amount of meat and bone meal to the feed for pigs, chickens, ducks, and other livestock can enhance their growth performance and feed conversion rate. When applied to aquatic feeds, it can meet the demand for high-quality protein in fish, shrimp, and other aquatic animals, promoting their growth and development, and improving farming efficiency.

Process characteristics

High temperature and high pressure cooking

· Complete sterilization: In a high-temperature and high-pressure environment, it can effectively kill harmful microorganisms such as bacteria, viruses, and parasites in meat and bones, including common ones like E. coli and Salmonella, ensuring the hygiene and safety of the product. For example, steaming for a certain period under 121℃,0.1MPa pressure can achieve a kill rate of over 99% for harmful microorganisms.

· Break down anti-nutritional factors: some anti-nutritional factors in meat and bone, such as trypsin inhibitor, will be destroyed under high temperature and high pressure conditions, so as to improve the nutritional value of meat and bone powder and the digestion and absorption rate of nutrients by animals.

· Softening the meat tissue: It is helpful for subsequent crushing, fat removal and other process operations, and improves production efficiency and product quality. For example, after cooking, the hardness of the meat tissue is significantly reduced, making it easier to be crushed into small particles.

High efficiency of fat removal

· Reducing Fat Content: By using physical or chemical methods to remove fat from meat and bone, the fat content in meat and bone meal can be controlled at a lower level. Typically, this reduces the fat content from the original 30% -40% to below 10%. This helps improve the stability and shelf life of meat and bone meal, reduces the unpleasant odors and harmful substances caused by fat oxidation and rancidity, and also avoids issues such as obesity due to excessive energy intake from animals.

· Increase protein content: The process of fat removal is actually the process of purifying meat powder. After removing a large amount of fat, the relative content of protein is increased, thus enhancing the value of meat powder as an animal feed protein source.

FAQ:

Q: What are the payment terms?

A: T/T, L/C and trade assurance are acceptable, T/T will be more appreciated, 30% deposit before production, 70% balance before

shipment.

Q: What is the delivery time?

A: At least 2 month after the deposit for most machines.

Q: How to pack the machine?

A: Standard packaging.

Q: How to install after the machines arriving destination?

A: Our engineer will go to customers site if you need, but need to pay installation fee according to the contract.

Q: What's the capacity you can do?

A: We always produce any capacity depend on customer needs.

-

Address

Shunwang Avenue, Zhucheng City, Shandong Province, China

-

Tel

-

E-mail

Contact Us

Shunwang Avenue, Zhucheng City, Shandong Province, China

Copyright © 2024 Shandong Chengming Environmental Protection Technology Co., Ltd. All Rights Reserved.