Email Us

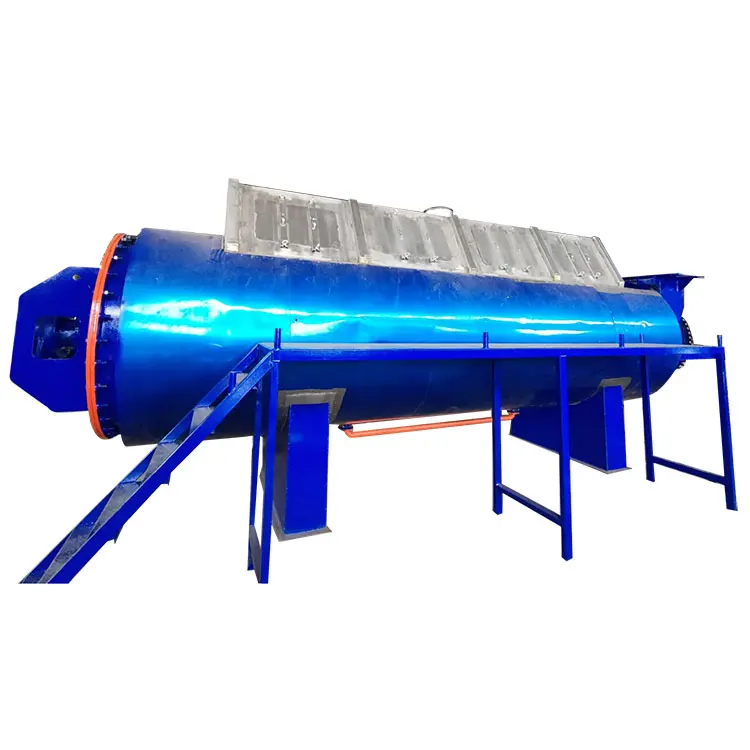

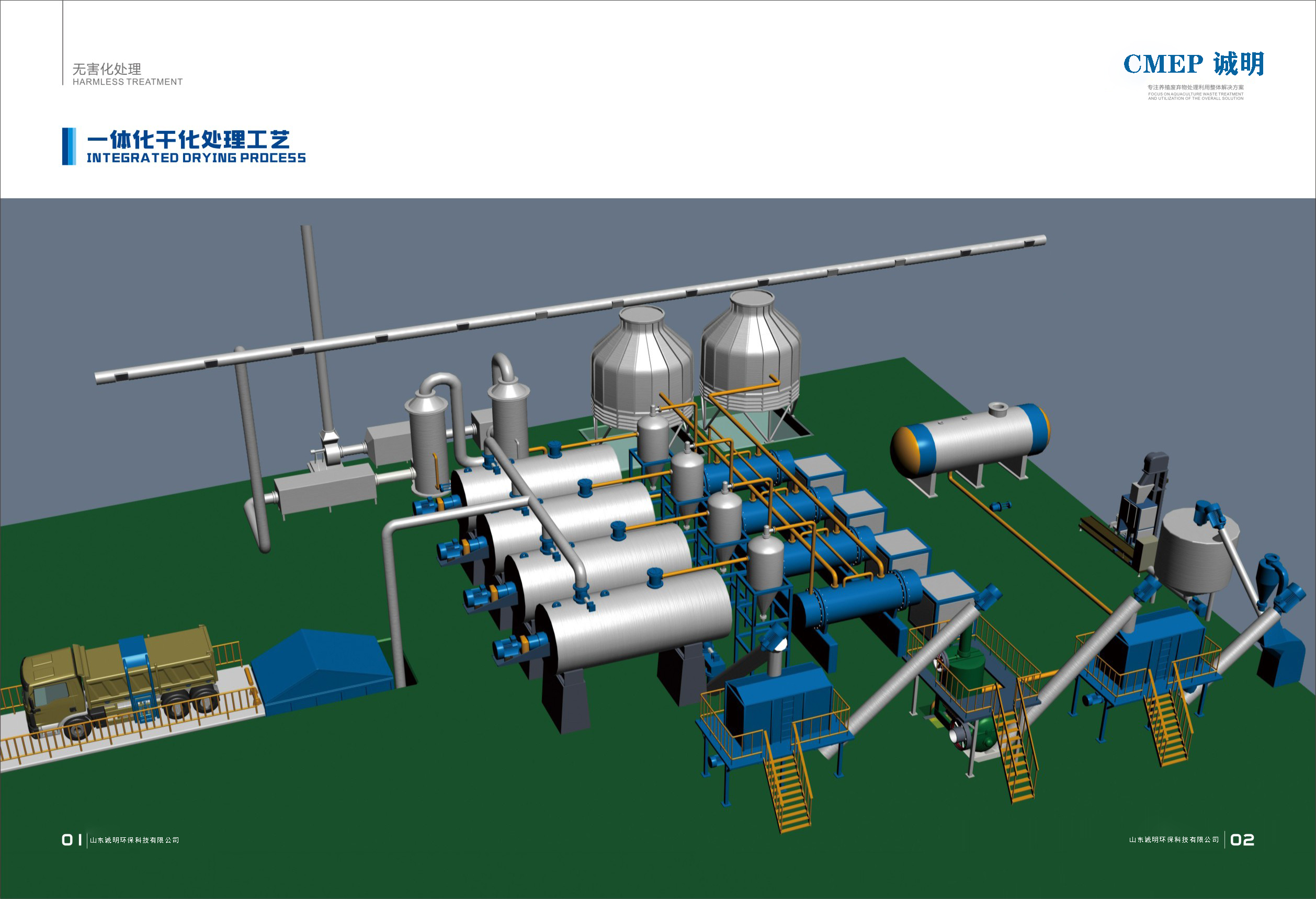

Animal Oil Refining Press Equipment: Purification efficiency and stable performance in oil processing

Animal Oil Refining Press Equipment has become the core equipment in the field of animal oil processing with its efficient oil purification ability and stable continuous operation performance. Its core value lies in achieving efficient extraction and purity improvement of animal oil through precise pressing and refining processes, while ensuring the continuity of the processing process and reducing production interruptions caused by equipment problems.

Technical core of purification process

The purification efficiency of Animal Oil Refining Press Equipment comes from its scientific process design. The pressing component inside the equipment adopts a special curved surface structure, which can gradually squeeze the raw materials through gradient pressure changes, maximize the separation of oil and residue, and reduce oil residue. The refining stage uses a temperature control system to accurately control the temperature, and cooperates with a filtering device to remove impurities and odor substances in the oil to improve the purity and quality of the oil. This synergistic effect of pressing and refining allows the final output of animal oil to meet high-quality standards in color, smell and purity.

Stable guarantee for continuous operation

In the production process, the continuous operation capacity of the equipment directly affects the processing efficiency, and Animal Oil Refining Press Equipment performs outstandingly in this regard. Its power transmission system adopts high-strength transmission components, which can maintain stable output power during long-term operation and avoid shutdowns caused by overload. The automated design of the feeding and discharging devices realizes the smooth connection between raw material supply and finished product output, reducing the pauses caused by manual intervention. At the same time, the equipment's heat dissipation system can effectively control the temperature during operation, prevent the performance stability from being affected by overheating, and ensure the continuous advancement of the production process.

Adaptability of raw material processing

Animal Oil Refining Press Equipment has good adaptability to different types of animal raw materials. Whether it is solid animal fat blocks or semi-solid raw materials, the equipment can achieve effective processing by adjusting the pressing parameters. Its internal anti-stick coating reduces the adhesion of raw materials during processing and ensures smooth processing; and the adjustable pressing gap can adapt to the characteristics of different raw materials, while ensuring the oil yield, avoiding the mixing of residues caused by excessive pressing, and ensuring the consistency of oil quality.

Balanced design of energy consumption and environmental protection

From a practical point of view, Animal Oil Refining Press Equipment has advantages in energy consumption control and environmental protection performance. The power system of the equipment adopts energy-saving motors to reduce power consumption while ensuring processing efficiency; the residues generated during the processing can be collected through a dedicated channel to facilitate subsequent resource utilization and reduce waste emissions; some equipment is also equipped with exhaust gas treatment devices to reduce the spread of odors generated during the processing, which meets the environmental protection requirements of modern production. These designs allow the equipment to improve production efficiency while taking into account the concept of green production.

Shandong Chengming Environmental Protection Technology Co., Ltd. relies on its professional experience in the field of industrial equipment to provide users with high-quality Animal Oil Refining Press Equipment products. The company focuses on the purification efficiency and operation stability of the equipment to ensure that the products can meet the needs of animal oil processing of different scales, provide reliable equipment support for the production process, and help improve processing efficiency and product quality.

- What Is a Feather Powder Dryer and How Does It Improve Rendering Efficiency?

- What Makes a Machine Making Feather Powder Essential for Modern Recycling Industries?

- Why Should You Choose Animal Harmless Treatment Equipment for Your Facility?

- Why Is a Grain Sterilization Tank Essential for Modern Food Processing?

- What is Animal Oil Refining Equipment and Why is it Essential?

- Why Choose a Harmless Treatment Humidifier for Your Air Quality Needs?

Contact Us

Shunwang Avenue, Zhucheng City, Shandong Province, China

Copyright © 2024 Shandong Chengming Environmental Protection Technology Co., Ltd. All Rights Reserved.