Email Us

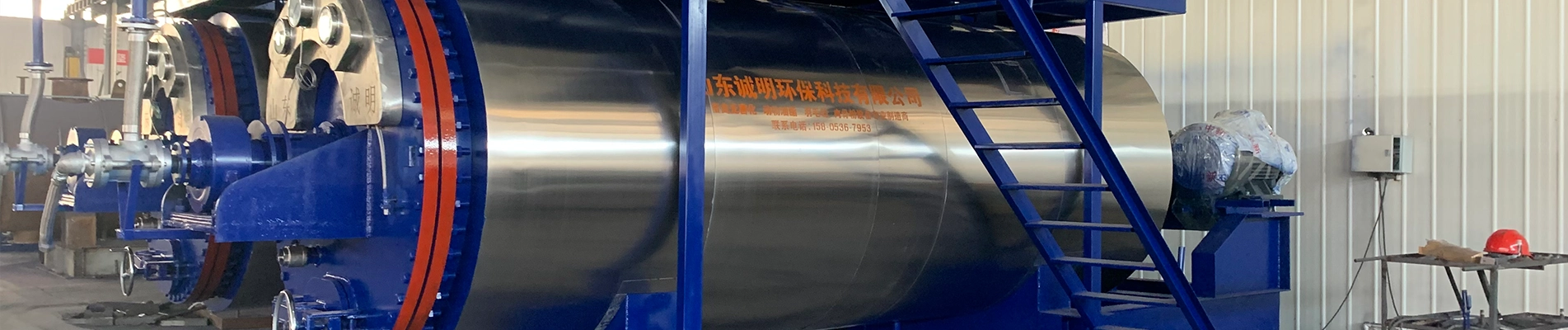

Coil Harmless Treatment Dryer

Coil dryer

Shandong Chengming Environmental Protection is a company dedicated to the research, design, production, and sales of complete sets of coil drying equipment. Located at No.10616 Shunwang Avenue, Zhucheng City, Shandong Province, the company covers an area of 20,000 square meters, with a factory occupying 8,000 square meters. It focuses on the production and R&D of harmless treatment equipment. The company has obtained——ISO9001 Quality Management System certification, ISO14001 Environmental Management System certification, and OHSAS18001 Occupational Health and Safety Management System certification. Additionally, it holds various manufacturing permits related to its products. Products are manufactured strictly according to design standards, making it a——national industry standard drafting unit for harmless treatment equipment and a member of the China Harmless Treatment Equipment Professional Committee.

For many years, we have provided professional equipment and technical services to customers. We mainly produce harmless treatment equipment for livestock and poultry, harmless treatment equipment for farms, harmless treatment equipment for dead animals, feather powder processing equipment, meat and bone powder processing equipment, animal fat refining equipment, wetting machines, feather powder dryers, etc.

Our company produces excellent equipment at a reasonable price. In the process of transaction, we not only provide you with professional pre-sale services, but also have perfect after-sales service to ensure that you get more than you pay for experience. We look forward to becoming your long-term partner in China.

Description

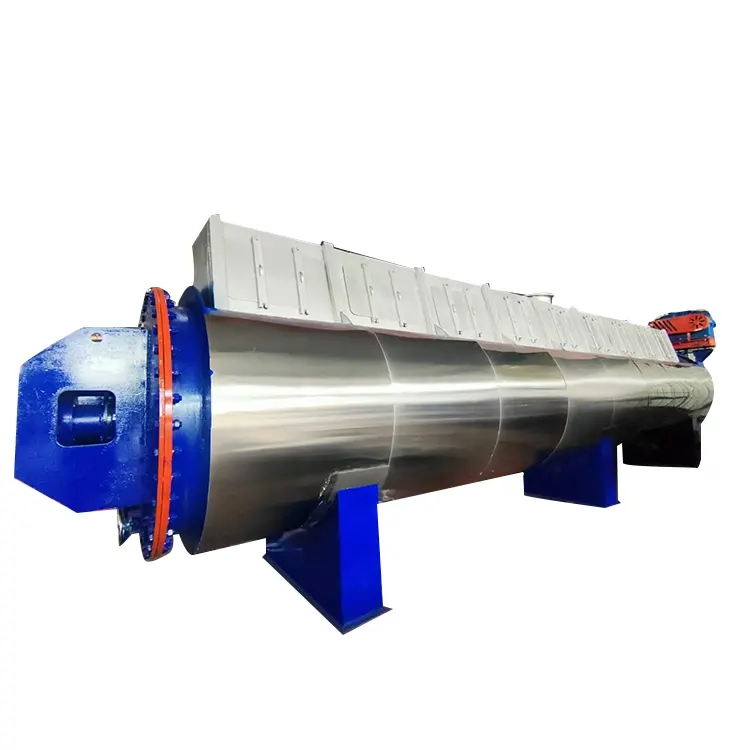

This coil harmless treatment dryer is an efficient conductive continuous drying equipment. The machine transfers heat to the material through the heat transfer wall, with part of the steam entering the annular space between the outer shell and the inner cylinder wall, heating the material via the inner wall, and condensate water being discharged from the bottom drainage port; another portion of the steam enters the main shaft and coil, heating the main shaft and coil, with condensate water being discharged from the steam rotary joint. As the shaft rotates, the material is thoroughly agitated and mixed under the combined action of the blades and the coil, ensuring maximum contact between the material and the shaft and coil. Secondary steam is discharged from the top chamber of the outer shell through the induced draft duct, maintaining a slight vacuum inside the duct to prevent waste steam from leaking out and to avoid absorbing too much cold air. The material distributor plate installed on the main shaft is located between the heating coils, which not only pushes the material forward but also has a self-cleaning function, capable of removing the covering layer on the shaft and cylinder walls to maintain good heat transfer performance.

Parameters

|

model |

Tank diameter |

length of tank |

Heat dissipation area |

power of motor |

working pressure |

|

CMH-1 |

φ1400 |

3062mm |

7.2㎡ |

37kW |

0.6MPa |

|

CMH-2 |

φ1400 |

3780mm |

9.37㎡ |

37kW |

0.6MPa |

|

CMH-3 |

φ1400 |

4436mm |

22.27㎡ |

37kW |

0.6MPa |

|

CMH-4 |

φ1400 |

7000mm |

25.09㎡ |

55kW |

0.6MPa |

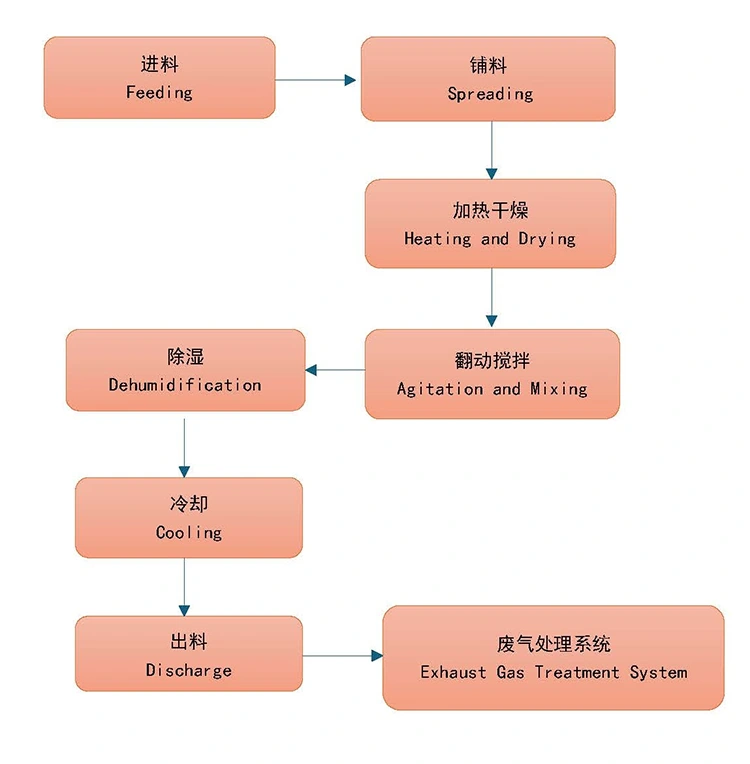

Coil dryer process flow

The process flow of coil dryer usually includes the following steps:

1. Feed: Wet material is evenly fed into the coil dryer through the feed system. The feed system can be a screw conveyor, belt conveyor or other type of feed device.

2. Material laying: The material is evenly spread on the surface of the coil. The coil is usually made of metal and flows with a hot medium (such as steam or hot oil) inside, indirectly heating the material through the coil wall.

3. Heating and drying: The heat medium circulates in the coil to transfer heat to the coil and then heat the material. The water in the material is gradually evaporated under the heating effect.

4. Stirring: In order to ensure uniform drying of the material, the coil dryer may be equipped with a stirring device to stir the material regularly to avoid clumping or uneven drying of the material.

5. Drying: The evaporated water is discharged through the drying system of the dryer. The drying system usually includes a fan and a drying pipe to ensure that the internal humidity and temperature of the dryer are maintained at an appropriate level.

6. Cooling: The dried material may need to be cooled for subsequent packaging or processing. Cooling can be achieved through natural cooling or forced cooling systems.

7. Discharge: The dried and cooled material is discharged from the dryer through the discharge system. The discharge system can be a screw conveyor, vibrating conveyor or other type of discharge device.

8. Heat recovery: In order to improve energy efficiency, some coil dryers are equipped with heat recovery system to recover and reuse the heat in the discharged hot and humid air, reducing energy consumption.

9. Automatic control: Modern coil dryer is usually equipped with an automatic control system, real-time monitoring and adjustment of temperature, humidity, feed rate and other parameters to ensure the stability and efficiency of the drying process.

The whole process is designed to remove moisture from materials efficiently and evenly while maintaining the quality and characteristics of materials. Coil dryer is widely used in chemical, food, pharmaceutical and other industries, suitable for drying various granular, powder and paste materials.

Applicable scope

Coil dryer is suitable for drying treatment of various industries and materials due to its efficient and uniform heating method and flexible operation characteristics. The following is the main application scope of coil dryer:

1. Pharmaceutical industry:

Used for drying raw materials, intermediates and finished products of drugs, such as Chinese medicine extracts, powder, tablets, etc.

Suitable for materials with high requirements of hygiene and cleanliness.

2. Environmental protection industry:

Used for drying sludge, kitchen waste and other wastes, reduce the volume and weight, facilitate subsequent treatment or resource utilization.

Suitable for materials that need high temperature sterilization and deodorization.

3. Agriculture:

Used for drying feed, fertilizer, crops, etc., to improve storage stability and use efficiency.

Suitable for materials that need to maintain nutrients and prevent mold.

The coil dryer has a wide range of applications and can meet the drying needs of different industries and materials. Its characteristics of high efficiency, energy saving and simple operation make it one of the indispensable drying equipment in modern industrial production.

Widely used in: feather powder, meat bone powder, kitchen waste, distillery waste, vinegar waste, bean residue, graphene and other powdered and granular materials.

Advantages

1. The outer jacket and main shaft coil or steam box are used to increase the heating area. Its unique structure and working principle determine that it has the characteristics of high thermal efficiency, low energy consumption, convenient operation control, good operating environment and so on.

2. The material plate installed on the spindle is located between the heating coil. It can not only push the material forward, but also has self-cleaning function. The moving heating can fully contact with the conductor;

3. The exhaust hood and pipe are made of stainless steel to improve corrosion resistance and prolong service life.

4. Use the automatic water conveying system to recover the steam condensate to the boiler to reduce energy consumption and save water.

-

Address

Shunwang Avenue, Zhucheng City, Shandong Province, China

-

Tel

-

E-mail

Contact Us

Shunwang Avenue, Zhucheng City, Shandong Province, China

Copyright © 2024 Shandong Chengming Environmental Protection Technology Co., Ltd. All Rights Reserved.