Email Us

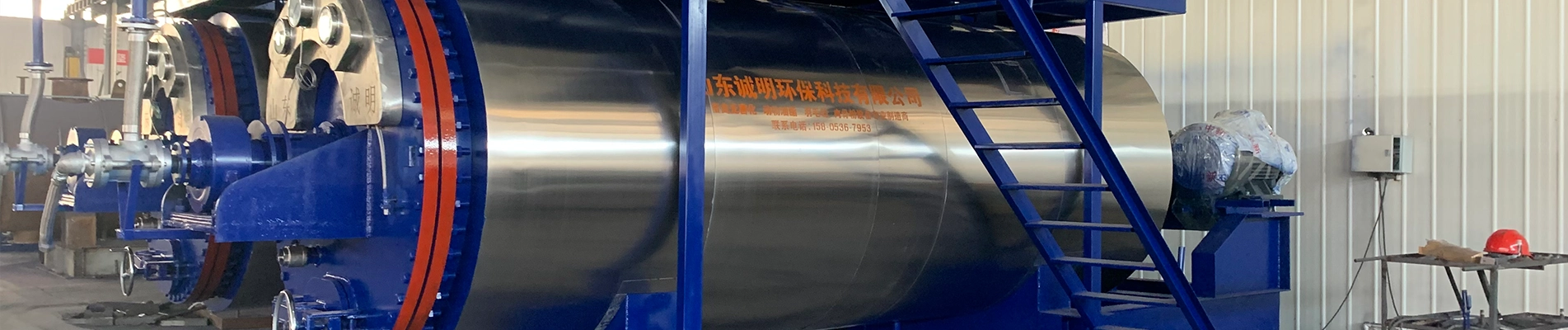

Harmless Treatment Equipment

- View as

Farms Harmless Treatment Equipment for Dead Chickens Ducks

The farms harmless treatment equipment for dead chickens ducks is a newly developed small-scale harmless treatment integrated machine for livestock and poultry based on market demand. It is easy to install and has no exhaust gas or wastewater discharge. Automatic control effectively avoids personnel from contacting dead animals to prevent cross infection and block the spread of germs.

Farms Harmless Treatment Equipment for Dead Chickens

The farms harmless treatment equipment for dead chickens is a newly developed small-scale harmless treatment integrated machine for livestock and poultry based on market demand. It is easy to install and has no exhaust gas or wastewater discharge; automatic control effectively avoids personnel from contacting dead animals to prevent cross infection and block the spread of germs; the whole is closed, does not seep liquid, does not leak air, and can effectively avoid environmental pollution; it is suitable for use in small and medium-sized farms and slaughterhouses, and the dead livestock and poultry are harmlessly treated nearby, not transported out, to prevent cross-transmission of germs; the solid products obtained can be used as raw materials for the production of organic fertilizers, and the fat can be made into industrial oil, turning waste into treasure; this machine can use electric heating steam or steam boiler; the whole treatment process takes 3-4 hours, and 100kg-2T of dead livestock and poultry can be treated each time according to different models.

Farms Harmless Treatment Equipment for Dead Cattle

Farms harmless treatment equipment for dead cattle refers to the process of crushing dead animal carcasses and transporting them to a closed container. While stirring continuously, the dead livestock and poultry carcasses are sterilized at high temperature and high pressure by introducing a high-temperature circulating heat source in the interlayer to eliminate the pathogens carried by them and eliminate the harm of animal carcasses. During the treatment process, the heat source does not directly contact the dead animal carcasses. The water in the animal body is heated and vaporized to generate pressure. After the chemical treatment is completed, vacuum drying, degreasing, cooling, crushing and other processes are carried out to finally obtain meat and bone powder dry products and industrial oils. It is currently the first treatment method recognized internationally.

Farms Harmless Treatment Equipment for Dead Pigs

The principle of the Farms harmless treatment equipment for dead pigs is to use high-temperature and high-pressure saturated steam to directly contact livestock and poultry, place all livestock and poultry in a high-temperature and high-pressure environment, dissolve fats, and hydrolyze proteins with wet heat. At the same time, with the help of high temperature and high pressure, all pathogens carried by livestock and poultry are sterilized.

Large Farm Harmless Treatment Equipment

Large Farm Harmless Treatment Equipment refers to the process of crushing dead animal carcasses and transporting them to a closed container. While stirring continuously, the dead animal carcasses are sterilized at high temperature and high pressure by introducing a high-temperature circulating heat source in the interlayer to eliminate the pathogens carried by them and eliminate the harm of animal carcasses. During the treatment process, the heat source does not directly contact the dead animal carcasses. The water in the animal body is heated and vaporized to generate pressure. After the chemical treatment is completed, vacuum drying, degreasing, cooling, crushing and other processes are carried out to finally obtain meat and bone powder dry products and industrial oils. It is currently the first treatment method recognized internationally.

Small Farm Harmless Treatment Equipment

The treatment method of small farm harmless treatment equipment is to use high-temperature and high-pressure saturated steam to directly contact the livestock and poultry carcasses, place the livestock and poultry carcasses in a high-temperature and high-pressure environment, melt the fat, and hydrolyze the protein by wet heat. At the same time, with the help of high temperature and high pressure, the pathogens carried in the livestock and poultry carcasses are killed.

We are looking forward to your buy Harmless Treatment Equipment from our company made in China - Chengming Environmental Protection. Our factory is a Harmless Treatment Equipment manufacturer and supplier in China. You are welcome to buy our high quality products.

Contact Us

Shunwang Avenue, Zhucheng City, Shandong Province, China

Copyright © 2024 Shandong Chengming Environmental Protection Technology Co., Ltd. All Rights Reserved.