Email Us

Harmless Treatment Equipment

- View as

High Temperature Drying Machine for Harmless Treatment

High temperature drying machine for harmless treatment mainly uses high temperature and high pressure sterilization process (121-150℃) to sterilize the dead livestock and poultry carcasses that need to be pre-crushed to achieve the complete killing of pathogens in the carcasses.

High Temperature Livestock Poultry Harmless Treatment Equipment

High temperature livestock poultry harmless treatment equipment process adopts the following steps: dead livestock and poultry spiral conveyor bin → closed body crushing treatment → closed spiral conveyor → high temperature and high pressure chemical treatment, degradation and drying → pressing → spiral conveyor → discharging; grease produced during pressing → oil storage tank (with self-heating system); the treated material is used as raw material for organic fertilizer (protein content above 50%); the obtained grease is used for industrial oil or refining biodiesel.

Small-scale Harmless Treatment Equipment

Small-scale Harmless Treatment Equipment refers to the process of crushing dead animal carcasses and transporting them to a closed container. While stirring continuously, the dead livestock and poultry carcasses are sterilized at high temperature and high pressure by introducing a high-temperature circulating heat source in the interlayer to eliminate the pathogens carried by them and eliminate the harm of animal carcasses.

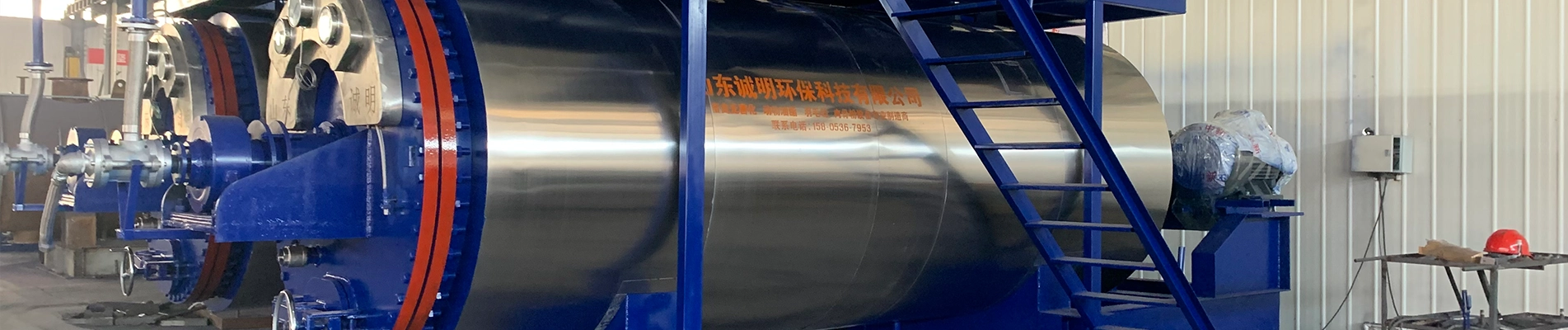

Large-scale Harmless Treatment Equipment

The working principle of large-scale harmless treatment equipment is to crush the dead animal carcasses and transport them into a closed container. While constantly stirring, the dead livestock and poultry carcasses are sterilized at high temperature and high pressure by introducing a high-temperature circulating heat source in the interlayer to kill the pathogens they carry and eliminate the hazards of the animal carcasses.

Complete Set of Harmless Treatment Equipment

Shandong Chengming Environmental Protection is a company dedicated to the research, design, production, and sales of comprehensive complete set of harmless treatment equipment. Located at No.10616 Shunwang Avenue, Zhucheng City, Shandong Province, the company covers an area of 20,000 square meters, with its factory occupying 8,000 square meters. It focuses on the production and R&D of harmless treatment equipment.

Livestock and Poultry Harmless Treatment Equipment

Shandong Chengming Environmental Protection is a company dedicated to the research, design, production, and sales of comprehensive livestock and poultry harmless treatment equipment.

We are looking forward to your buy Harmless Treatment Equipment from our company made in China - Chengming Environmental Protection. Our factory is a Harmless Treatment Equipment manufacturer and supplier in China. You are welcome to buy our high quality products.

Contact Us

Shunwang Avenue, Zhucheng City, Shandong Province, China

Copyright © 2024 Shandong Chengming Environmental Protection Technology Co., Ltd. All Rights Reserved.