Email Us

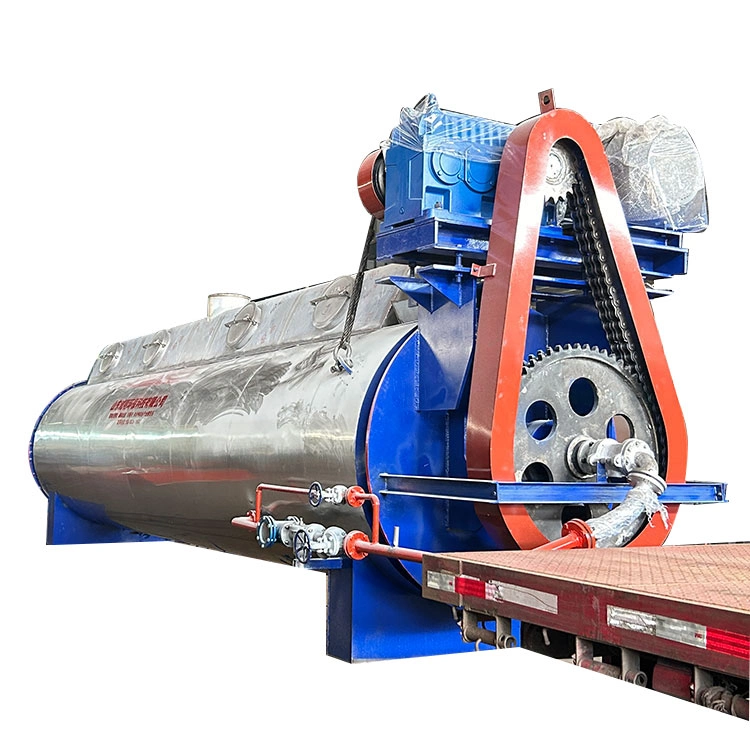

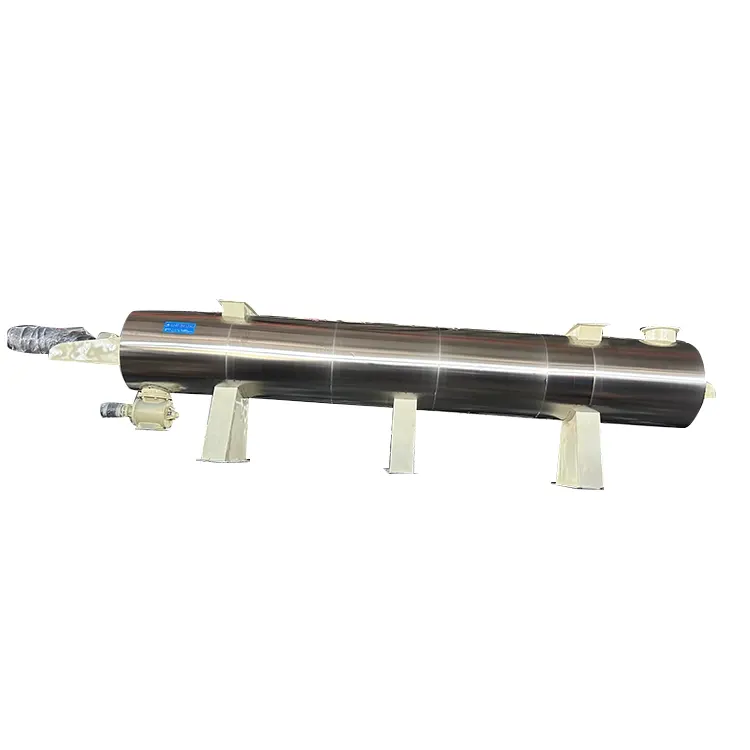

Daily maintenance and care of animal harmless treatment equipment.

The key points of daily maintenance of animal harmless treatment equipment include cleaning, lubrication and inspection. Cleaning means regularly cleaning the equipment to remove dust, dirt and residues on the surface of the equipment and keep the equipment clean. Lubrication is to lubricate the moving parts of the equipment to reduce wear and extend the service life of the equipment. Inspection includes inspecting various parts of the equipment, such as checking the sealing of the equipment and the connection of the electrical system, and finding and dealing with problems in time.

The content and requirements of regular overhaul mainly include the replacement of equipment parts and the debugging of the system. For some wearing parts, such as seals and filters, they need to be replaced regularly to ensure the normal operation of the equipment. System debugging includes debugging the control system and transmission system of the equipment to ensure the stable performance of each system.

Correct maintenance has an important impact on the service life of equipment. Through regular cleaning, lubrication and inspection, potential problems of the equipment can be found in time to avoid the expansion of problems. Regular replacement of wearing parts and system debugging can ensure the stable performance of the equipment and extend the service life of the equipment. At the same time, good maintenance can also improve the reliability and stability of the equipment, reduce the occurrence of equipment failures and improve the operating efficiency of the equipment.

Contact Us

Shunwang Avenue, Zhucheng City, Shandong Province, China

Copyright © 2024 Shandong Chengming Environmental Protection Technology Co., Ltd. All Rights Reserved.