Email Us

What Makes a Machine Making Feather Powder Essential for Modern Recycling Industries?

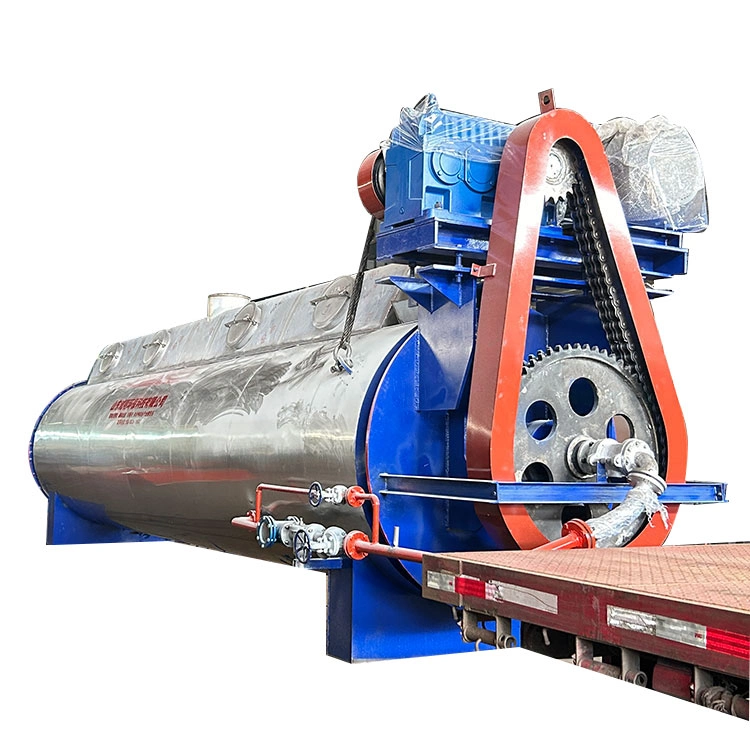

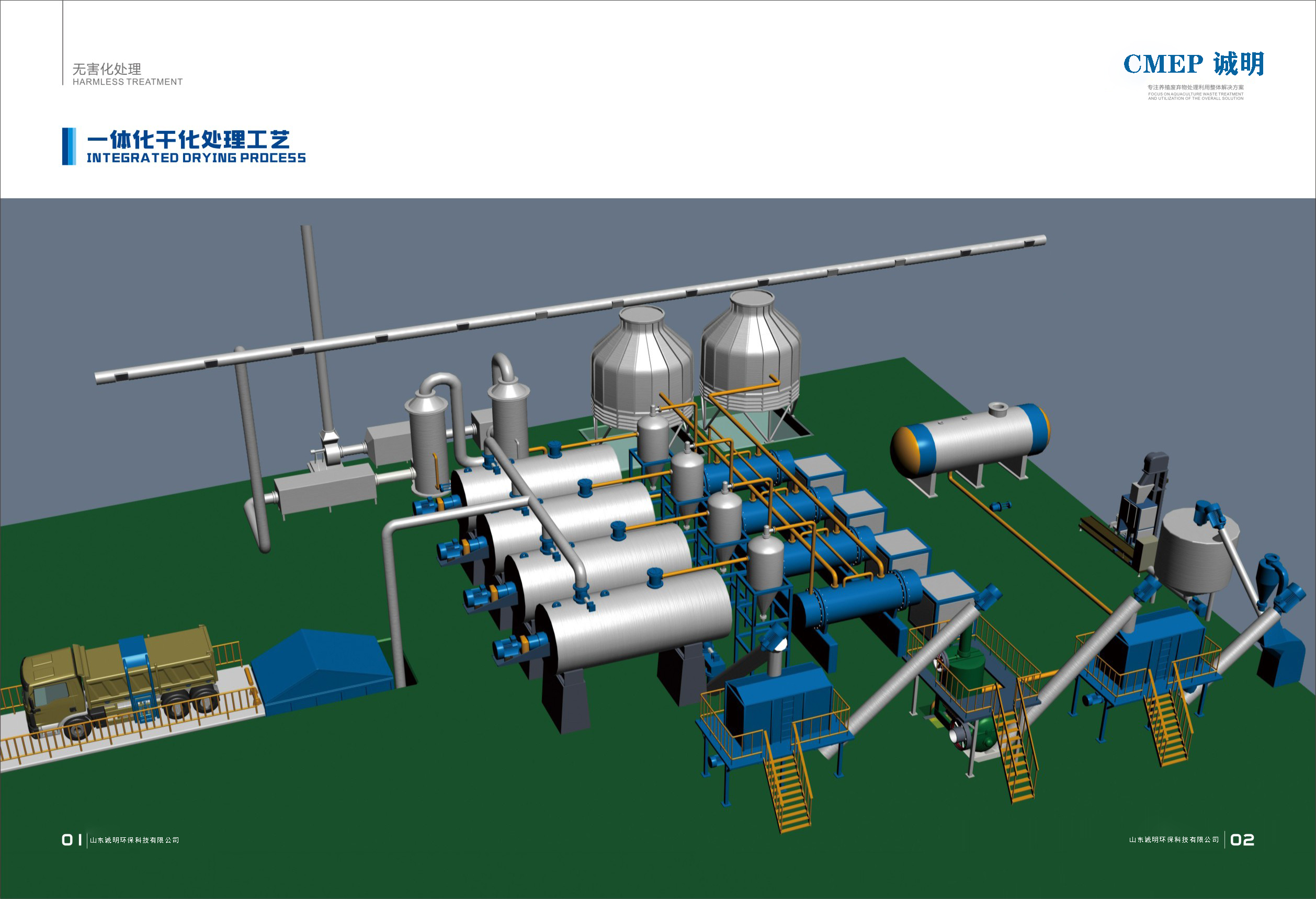

Feather waste generated by poultry processing plants has become one of the most challenging organic by-products to manage. Converting this waste into high-value feather powder offers a sustainable, economical, and environmentally responsible solution. A Machine Making Feather Powder plays a crucial role by transforming raw feathers into uniform, digestible, and nutrient-dense powder widely used in feed, fertilizer, and other industrial applications. This article explains how the machine works, why it matters, how to choose the right model, and what parameters to look for when sourcing equipment from professional manufacturers such as Shandong Chengming Environmental Protection Technology Co., Ltd.

Why Is a Machine Making Feather Powder Important for Waste Recycling?

A Machine Making Feather Powder provides several functions that contribute to modern environmental protection and industrial efficiency:

-

Reduces organic waste from poultry slaughterhouses

-

Improves resource utilization by turning feathers into useful powder

-

Decreases pollution caused by improper disposal

-

Creates an additional revenue stream for feed and fertilizer producers

-

Enhances processing safety through sterilization and high-temperature treatment

By integrating a reliable system, companies can meet environmental standards and reduce operational costs.

How Does a Machine Making Feather Powder Work?

The processing workflow typically includes:

-

Feather Collection & Pre-Treatment – Feathers are washed and dewatered.

-

High-Temperature Hydrolysis – The machine breaks down keratin fibers into digestible protein.

-

Drying Process – Moisture is removed to ensure a stable, powdery final product.

-

Grinding & Pulverizing – Material is ground to a uniform fineness.

-

Final Sterilization – Eliminates pathogens and ensures feed-grade safety.

-

Automatic Discharge – Powder is collected for packaging or storage.

This technology ensures consistency, safety, and high conversion efficiency.

What Are the Key Product Parameters You Should Consider?

The following table summarizes typical technical parameters offered by manufacturers like Shandong Chengming Environmental Protection Technology Co., Ltd. These specifications may vary by model, but they represent core features customers commonly evaluate.

Product Parameter Table

| Parameter | Specification Range | Description |

|---|---|---|

| Processing Capacity | 500–3000 kg/h | Amount of feathers processed per hour |

| Heating Method | Steam / Electricity / Gas | Supports flexible energy options |

| Drying Temperature | 120–160°C | Ensures sterilization and moisture removal |

| Final Moisture Content | ≤10% | Helps maintain shelf stability |

| Powder Fineness | 40–120 mesh | Adjustable grinding level |

| Power Consumption | 20–75 kW | Depends on model capacity |

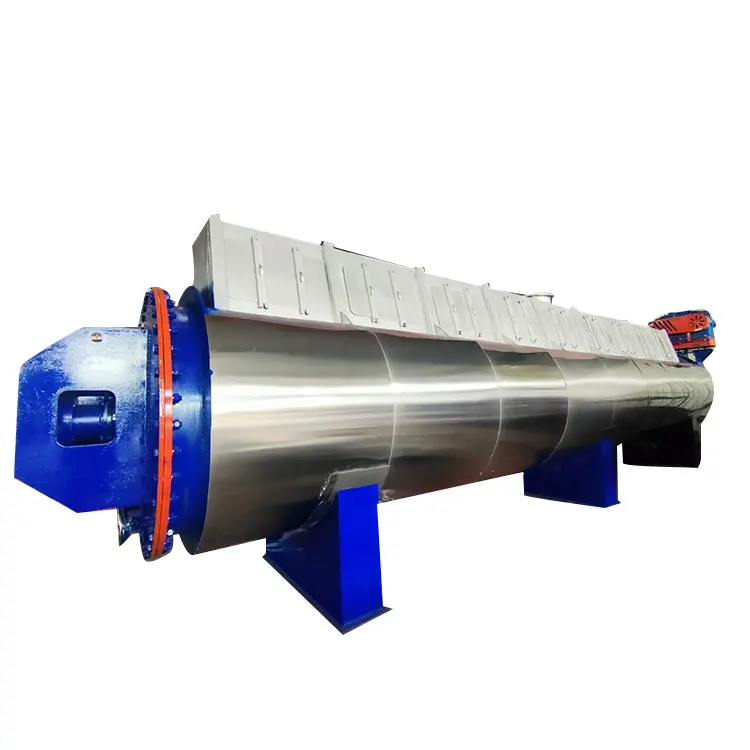

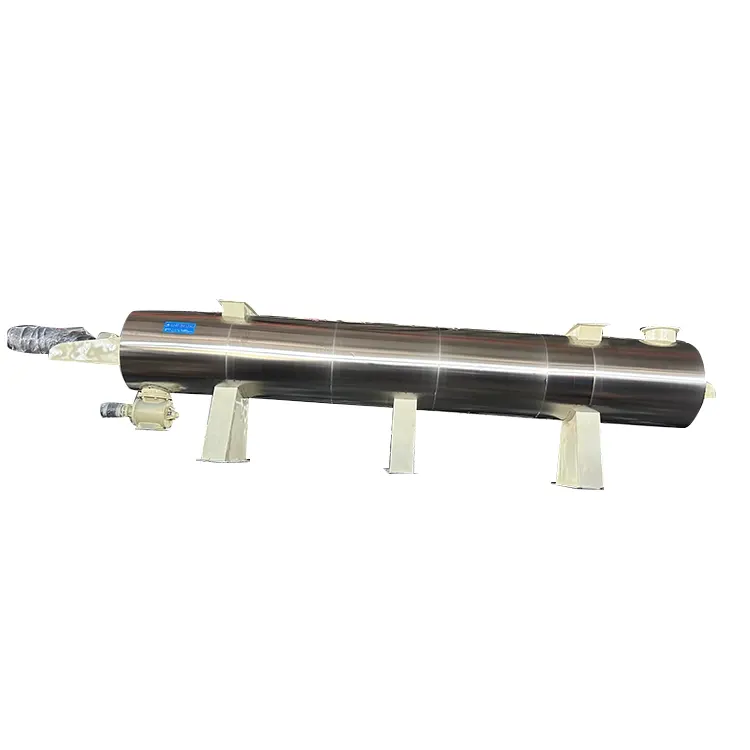

| Material of Construction | Stainless Steel 304/316 | Ensures hygiene and durability |

| Control System | PLC Automatic Control | Allows precise operation |

| Machine Size | Customized | Based on project scale |

Which Features Determine the Efficiency of a Machine Making Feather Powder?

A high-quality system should include:

-

High-temperature hydrolysis chamber for effective keratin breakdown

-

Energy-saving drying system to reduce operating costs

-

Advanced grinding blades for fine and consistent powder

-

Automatic feeding and discharge design for continuous production

-

Safety devices to control pressure, temperature, and airflow

-

Stainless-steel construction for corrosion resistance

These features determine the working efficiency, durability, and productivity of the machine.

What Benefits Can You Expect from Using a Machine Making Feather Powder?

Companies choose this equipment for several advantages:

-

Enhanced protein conversion rate

-

Lower waste treatment costs

-

Compliance with environmental regulations

-

Stable output quality suitable for various industries

-

Long service life and low maintenance requirements

-

Customizable designs tailored to production needs

Manufacturers such as Shandong Chengming Environmental Protection Technology Co., Ltd. offer solutions that integrate environmental protection with economic value, making them a trusted partner in the recycling sector.

How to Choose the Best Machine Making Feather Powder for Your Facility?

When selecting a model, consider the following:

Checklist for Selection

-

Expected daily output

-

Energy source availability

-

Level of automation required

-

Budget and long-term operating cost

-

Raw material cleanliness and moisture level

-

Installation space and workshop layout

-

After-sales support and spare parts availability

Choosing a reliable supplier ensures stable performance and long-term value.

FAQ About Machine Making Feather Powder

Q1: What industries can use the powder made by a Machine Making Feather Powder?

A1: The powder is widely used in animal feed production, organic fertilizer, aquaculture, and biological product manufacturing due to its high protein content and excellent nutrient value.

Q2: How does a Machine Making Feather Powder ensure product safety?

A2: The machine uses high-temperature hydrolysis, sterilization, and controlled drying to eliminate pathogens, ensuring the final powder meets feed-grade safety standards.

Q3: What is the maintenance requirement for a Machine Making Feather Powder?

A3: Routine maintenance includes lubricating moving parts, checking temperature sensors, cleaning filters, and inspecting the grinding chamber. High-quality machines require minimal downtime.

Q4: Can the machine operate continuously for large-scale production?

A4: Yes. Most models from professional manufacturers are designed for 24-hour continuous operation, featuring stable control systems and durable stainless-steel components.

Contact Information

For detailed specifications, project design, or customized service solutions, you may contact Shandong Chengming Environmental Protection Technology Co., Ltd. Their professional team offers complete equipment consultation and technical support tailored to different production needs.

- Why Should You Choose Animal Harmless Treatment Equipment for Your Facility?

- Why Is a Grain Sterilization Tank Essential for Modern Food Processing?

- What is Animal Oil Refining Equipment and Why is it Essential?

- Why Choose a Harmless Treatment Humidifier for Your Air Quality Needs?

- What Exactly is Chicken Feather Powder Equipment and How Can It Boost Your Profits?

- How is this feather meal production line innovative?

Contact Us

Shunwang Avenue, Zhucheng City, Shandong Province, China

Copyright © 2024 Shandong Chengming Environmental Protection Technology Co., Ltd. All Rights Reserved.