Email Us

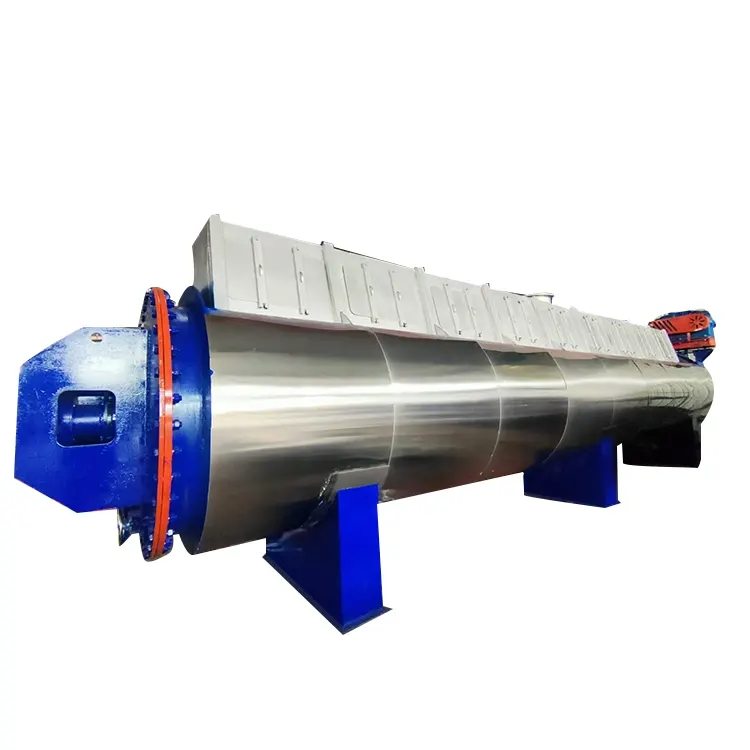

Feather meal equipment processing and left and right

Feather meal processing is a process that involves converting waste feathers into high-protein feed or fertilizer. The following is a detailed discussion of feather meal processing and its related aspects:

1. Overview of feather meal processing

Feather meal processing mainly includes the steps of collecting, cleaning, drying, crushing and packaging feathers. Through this process, feathers that were originally regarded as waste can be converted into valuable feed or fertilizer products.

1. Collection: The starting step of feather meal processing is to collect waste feathers. These feathers may come from poultry slaughterhouses, poultry farms or other related industries.

2. Cleaning: The collected feathers need to be cleaned to remove dirt, grease and other impurities attached to the feathers. The cleaning process may involve the use of water, detergents or other cleaning substances.

3. Drying: The cleaned feathers need to be dried to remove moisture. The drying process may involve the use of hot air, dryers or other drying equipment.

4. Crushing: The dried feathers need to be crushed by a crusher to convert them into a fine powdery substance. The purpose of this step is to increase the surface area of the feather meal and improve its utilization and nutritional value.

5. Packaging: Finally, the crushed feather meal needs to be packaged for storage and transportation. The packaging material should have good sealing and moisture resistance to ensure the quality and stability of the feather meal.

2. The impact of feather meal equipment processing (impact and application)

1. Impact on the environment: Feather meal equipment processing helps reduce the pollution of waste feathers to the environment. By converting waste feathers into valuable feed or fertilizer products, the demand for landfill and incineration can be reduced, thereby reducing the risk of environmental pollution.

2. Impact on the feed industry: Feather meal is a high-protein feed raw material with nutritional value comparable to fish meal, meat and bone meal, etc. Therefore, feather meal equipment processing provides a new and sustainable source of protein for the feed industry. This helps reduce feed costs, improve feed quality, and promote the sustainable development of animal husbandry.

3. Impact on agriculture: Feather meal can also be used as an organic fertilizer. Because it is rich in nutrients such as nitrogen, phosphorus, and potassium, feather meal fertilizer helps to improve soil fertility and promote crop growth. Therefore, feather meal equipment processing also provides a new and environmentally friendly fertilizer source for the agricultural field.

4. Impact on the economy: The development of the feather meal equipment processing industry helps to promote the prosperity of related industries and economic growth. For example, it can provide an additional source of income for poultry slaughterhouses, poultry farms, etc.; at the same time, it can also provide a new source of raw materials for feed and fertilizer producers. In summary, feather meal equipment processing not only helps to reduce environmental pollution and improve resource utilization, but also provides a new and sustainable source of raw materials for the feed and agricultural fields. With people's increasing attention to environmental protection and sustainable development, the feather meal equipment processing industry is expected to be more widely developed and applied in the future.

- Why Should You Choose Animal Harmless Treatment Equipment for Your Facility?

- Why Is a Grain Sterilization Tank Essential for Modern Food Processing?

- What is Animal Oil Refining Equipment and Why is it Essential?

- Why Choose a Harmless Treatment Humidifier for Your Air Quality Needs?

- What Exactly is Chicken Feather Powder Equipment and How Can It Boost Your Profits?

- How is this feather meal production line innovative?

Contact Us

Shunwang Avenue, Zhucheng City, Shandong Province, China

Copyright © 2024 Shandong Chengming Environmental Protection Technology Co., Ltd. All Rights Reserved.