Email Us

How Does a Grain Sterilization Tank Improve Food Safety Compliance?

Abstract

A Grain Sterilization Tank is a critical piece of equipment used in modern grain storage and processing systems to reduce microbial contamination, insect infestation, and fungal growth before downstream processing or long-term storage. This article examines how grain sterilization tanks operate, the core technical parameters that define performance, and how they align with increasingly strict food safety regulations. The discussion also addresses common operational questions, industry use cases, and the future direction of grain sterilization technology within global agricultural supply chains.

Table of Contents

- Article Outline

- Product Overview and Core Objective

- Technical Parameters and Configuration

- Operational Scenarios and Industry Adoption

- Grain Sterilization Tank FAQ

- Technology Development and Market Direction

- Conclusion and Manufacturer Reference

Article Outline

This article is structured around four core nodes: equipment fundamentals, technical configuration, operational application, and long-term industry evolution. Each section addresses “how” questions commonly searched by grain processors, storage operators, and regulatory stakeholders.

Product Overview and Core Objective

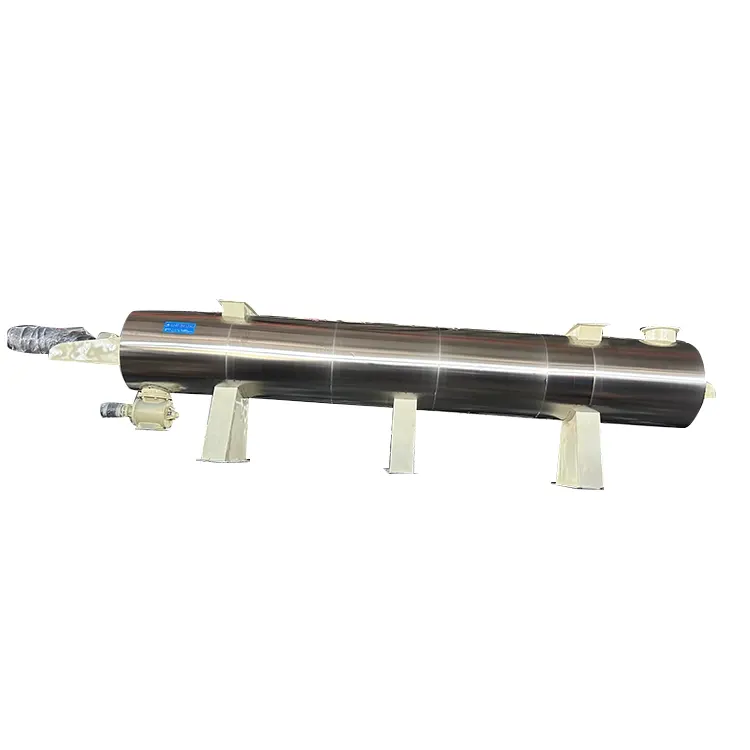

A Grain Sterilization Tank is designed to create a controlled internal environment in which bulk grains such as wheat, corn, rice, barley, or sorghum are exposed to physical or chemical sterilization methods. The primary objective is to lower biological risk factors before milling, packaging, or extended storage. Unlike surface-level treatment systems, the tank structure allows uniform penetration of sterilizing agents, ensuring consistency across large grain volumes.

The central theme of this article is how grain sterilization tanks contribute to compliance, operational stability, and risk management in modern grain handling systems. By understanding equipment parameters and working principles, operators can better align sterilization outcomes with export standards, food safety audits, and quality assurance frameworks.

Technical Parameters and Configuration

The performance of a Grain Sterilization Tank is defined by its structural design, material selection, control system, and sterilization method compatibility. Below is a consolidated representation of commonly referenced technical parameters used to evaluate professional-grade systems.

| Parameter | Typical Specification Range | Technical Relevance |

|---|---|---|

| Tank Capacity | 5–100 m³ | Determines batch size and processing throughput |

| Construction Material | Carbon Steel / Stainless Steel | Affects corrosion resistance and sanitation level |

| Sterilization Method | Gas, Heat, Ozone, or Integrated Systems | Defines microbial and pest control effectiveness |

| Operating Pressure | Normal or Slightly Pressurized | Supports controlled agent diffusion |

| Temperature Control | Ambient to 80°C (configurable) | Enhances sterilization reaction efficiency |

| Control System | PLC / Manual Hybrid | Ensures process repeatability and safety |

These parameters collectively determine how effectively the tank can integrate into existing grain handling lines, including conveyors, elevators, silos, and packaging units.

Operational Scenarios and Industry Adoption

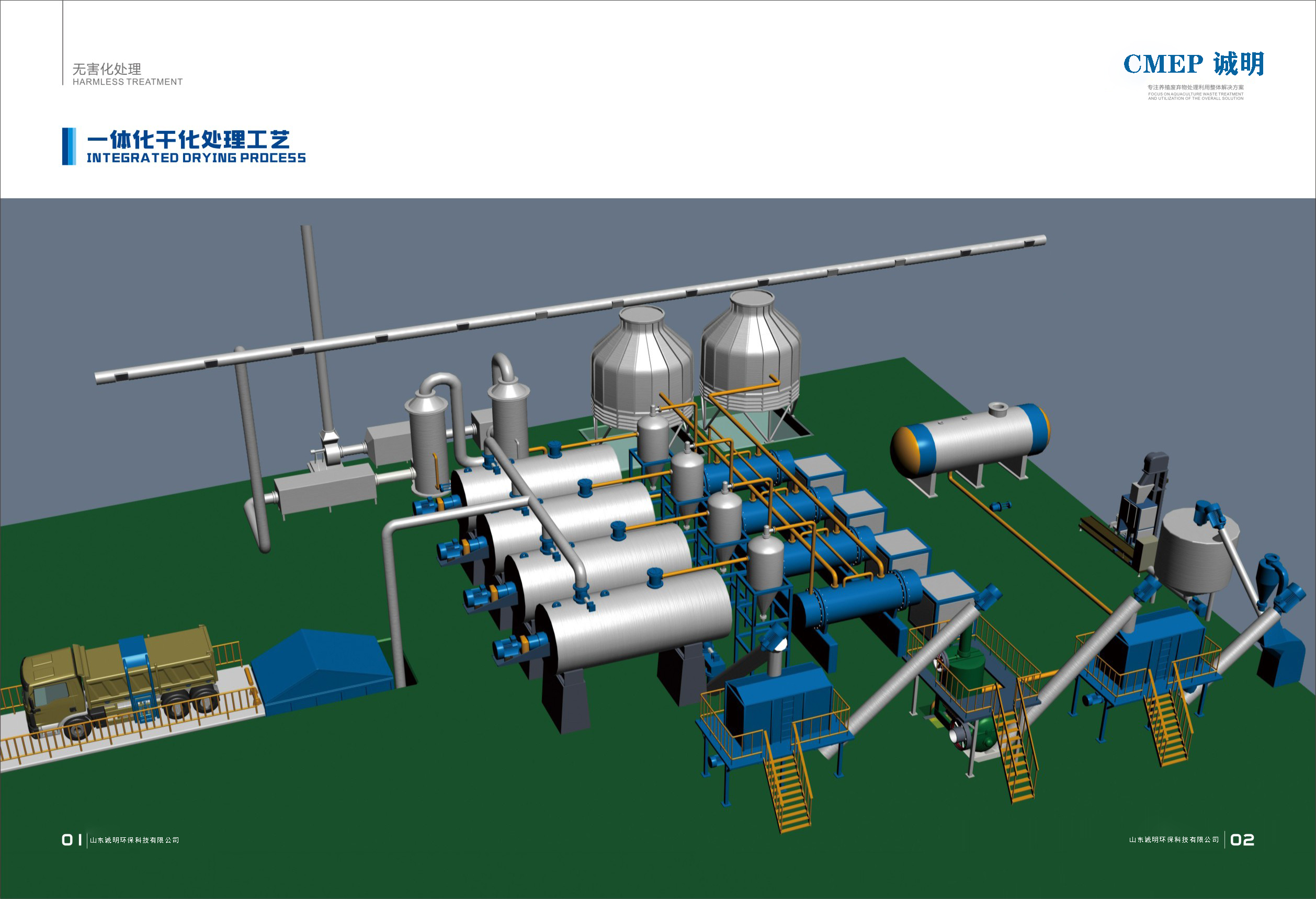

Grain Sterilization Tanks are widely deployed across grain storage depots, flour mills, feed processing plants, and export-oriented agricultural facilities. Their use is particularly relevant in regions where climatic conditions increase the likelihood of mold formation or insect reproduction.

From an operational standpoint, sterilization tanks are positioned upstream of milling or storage silos. This placement allows contaminated grain to be treated before it introduces systemic risk into the broader processing environment. Regulatory agencies increasingly recognize pre-storage sterilization as a proactive risk control measure.

Grain Sterilization Tank FAQ

Q: How does a grain sterilization tank achieve uniform treatment across large grain volumes?

A: Uniform treatment is achieved through controlled circulation systems and calibrated agent distribution points within the tank. Internal flow design ensures that sterilizing media reach all grain layers without creating concentration gradients.

Q: How long does a standard grain sterilization cycle take?

A: Cycle duration varies depending on grain type, moisture content, and sterilization method, but typical processing times range from 30 minutes to several hours, including ventilation and residue dissipation phases.

Q: How is operator safety ensured during sterilization processes?

A: Modern systems incorporate sealed tank structures, automated interlocks, gas detection sensors, and exhaust treatment units. These features collectively minimize human exposure and comply with industrial safety standards.

Technology Development and Market Direction

The future of grain sterilization tanks is shaped by automation, digital monitoring, and environmental compliance. Smart sensors and data logging capabilities are increasingly integrated to provide traceability for audits and export documentation. Additionally, low-residue and non-chemical sterilization approaches are gaining traction as sustainability requirements tighten.

From a market perspective, demand is driven by cross-border grain trade, stricter food safety legislation, and the professionalization of bulk grain storage infrastructure.

Conclusion and Manufacturer Reference

Grain Sterilization Tanks represent a foundational component in modern grain safety management systems. By enabling controlled, repeatable sterilization at scale, they support regulatory compliance, reduce post-harvest losses, and enhance overall supply chain reliability.

Within this evolving industry landscape, equipment manufactured by Shandong Chengming Environmental Protection Technology Co., Ltd. is increasingly applied in integrated grain processing and environmental control projects, reflecting the growing emphasis on system-level engineering and long-term operational stability.

For organizations seeking detailed technical consultation, customized configurations, or application guidance, interested parties are encouraged to contact us to discuss project-specific requirements and implementation strategies.

- What Is Meat Bone Meal Production Equipment and How Does It Work?

- What Is a Feather Powder Dryer and How Does It Improve Rendering Efficiency?

- What Makes a Machine Making Feather Powder Essential for Modern Recycling Industries?

- Why Should You Choose Animal Harmless Treatment Equipment for Your Facility?

- Why Is a Grain Sterilization Tank Essential for Modern Food Processing?

- What is Animal Oil Refining Equipment and Why is it Essential?

Contact Us

Shunwang Avenue, Zhucheng City, Shandong Province, China

Copyright © 2024 Shandong Chengming Environmental Protection Technology Co., Ltd. All Rights Reserved.