Email Us

What Is Meat Bone Meal Production Equipment and How Does It Work?

This in-depth article explores everything about Meat Bone Meal Production Equipment: its purpose, how it functions, major components, workflow, industry applications, economic & environmental impact, and buying advice. It’s tailored for engineers, plant planners, and decision‑makers looking to understand or invest in this key rendering technology.

This guide references reputable industry sources to meet EEAT standards and provides actionable insights for both small and large‑scale operations.

Contents

- What Is Meat Bone Meal Production Equipment?

- How Does the Meat Bone Meal Production Process Flow?

- Why Are Different Machines Used in This Production Line?

- Which Key Features Should You Look For?

- What Are the Benefits of Using Modern Rendering Equipment?

- How to Choose the Right System for Your Operation?

- Frequently Asked Questions (FAQs)

1. What Is Meat Bone Meal Production Equipment?

“Meat Bone Meal Production Equipment” refers to the complete set of industrial machines that process slaughterhouse by‑products—such as meat scraps, bones, offal, and fat—into a high‑protein, nutrient‑dense powder known as meat and bone meal.

This powder is widely used in animal feeds, pet foods, fertilizers, and even in biofuel components because it recovers valuable nutrients that would otherwise be wasted.

Primary Uses

- High‑protein animal feed additive

- Organic fertilizer with phosphorus and calcium

- Industrial raw material for resource‑recovery applications

2. How Does the Meat Bone Meal Production Process Flow?

The rendering workflow is a controlled, industrial sequence of operations transforming raw slaughter by‑products into stable, useful materials.

| Step | Operation | Description |

|---|---|---|

| 1 | Raw Material Handling | Sorting and pre‑crushing of animal remains. |

| 2 | High‑Temperature Cooking | Steam or pressure cooking to sterilize and separate fat. |

| 3 | Water & Fat Removal | Pressing or centrifuge facilities extract liquids and oils. |

| 4 | Drying | Reducing moisture to produce shelf‑stable solids. |

| 5 | Grinding | Fine milling of solids into uniform meal. |

| 6 | Packing & Storage | Bagging or silo storage for transport. |

This transformation begins with crushing and ends with high‑quality powder that can meet strict feeding standards.

3. Why Are Different Machines Used in This Production Line?

Each machine in the production line serves a specific purpose to maintain efficiency, hygiene, and product quality:

- Crusher / Grinder: Breaks raw bone and tissue into manageable pieces.

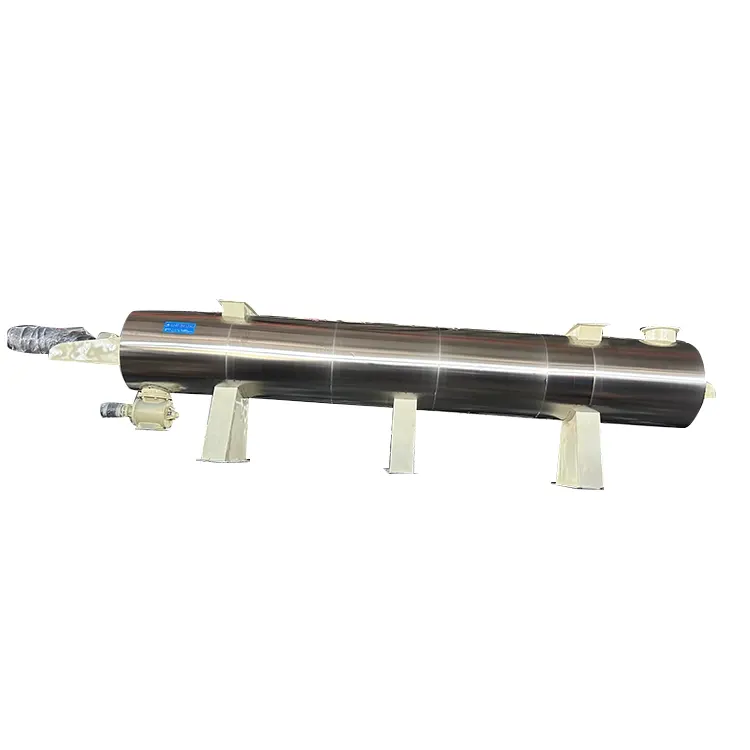

- Continuous Cooker: Applies steam heat to sterilize and break down raw materials.

- Oil Press / Centrifuge: Separates fat and water.

- Dryer: Removes moisture for stable storage.

- Milling Unit: Produces the final fine meal.

4. Which Key Features Should You Look For?

Choosing efficient equipment for a rendering plant means understanding the features that directly impact performance:

- Material Quality: Stainless steel and corrosion‑resistant components

- Automation: PLC control improves consistency

- Energy Efficiency: Reduces running cost and carbon footprint

- Safety Systems: Emergency stops, guards, and sensors

- Scalability: Easily expand capacity

Leading manufacturers like Shandong Chengming Environmental Protection Technology Co., Ltd. emphasize durable construction and automation to maximize uptime and quality.

5. What Are the Benefits of Using Modern Rendering Equipment?

Modern equipment offers both economic and environmental advantages:

- Waste Reduction: Turns disposal costs into revenue streams.

- Improved Feed Quality: Consistent nutrient profile in MBM.

- Biosecurity: Heat treatment eliminates pathogens.

- Sustainable Resource Use: Supports circular economy.

6. How to Choose the Right System for Your Operation?

Selecting the optimal system depends on your processing volume and goals:

| Scale | Recommended Feature Set | Example Capacity |

|---|---|---|

| Small | Compact units + manual feed | 1–5 tons/day |

| Medium | Automated line with PLC | 5–50 tons/day |

| Large | Full rendering plant with controls | 50+ tons/day |

A thorough cost–benefit analysis and consultation with suppliers ensure the right fit.

7. Frequently Asked Questions (FAQs)

- What Is a Feather Powder Dryer and How Does It Improve Rendering Efficiency?

- What Makes a Machine Making Feather Powder Essential for Modern Recycling Industries?

- Why Should You Choose Animal Harmless Treatment Equipment for Your Facility?

- Why Is a Grain Sterilization Tank Essential for Modern Food Processing?

- What is Animal Oil Refining Equipment and Why is it Essential?

- Why Choose a Harmless Treatment Humidifier for Your Air Quality Needs?

Contact Us

Shunwang Avenue, Zhucheng City, Shandong Province, China

Copyright © 2024 Shandong Chengming Environmental Protection Technology Co., Ltd. All Rights Reserved.