Email Us

How Does an Animal Carcass Crusher Support Regulated Animal Waste Disposal?

Abstract

How can animal carcasses be processed in a manner that aligns with environmental regulations, biosecurity requirements, and operational efficiency? This article provides a comprehensive examination of the Animal Carcass Crusher, focusing on how the equipment functions within animal waste treatment systems. The discussion centers on structural configuration, operational parameters, application scenarios, compliance considerations, and frequently asked technical questions. The objective is to clarify how this equipment supports standardized carcass size reduction as part of modern livestock and poultry waste management.

Outline

- Introduction: How Is an Animal Carcass Crusher Applied in Animal Waste Treatment?

- How Does an Animal Carcass Crusher Work in Practice?

- How Are Technical Parameters Defined for Different Disposal Scales?

- How Is the Equipment Integrated into Complete Disposal Systems?

- How Can Operational Questions About Animal Carcass Crushers Be Answered?

- How Is the Equipment Positioned Within Industry Development?

- How Can Reliable Manufacturers Be Identified?

Table of Contents

- How Is an Animal Carcass Crusher Applied in Animal Waste Treatment?

- How Does an Animal Carcass Crusher Work in Practice?

- How Are Technical Parameters Defined for Different Disposal Scales?

- How Is the Equipment Integrated into Complete Disposal Systems?

- How Can Operational Questions About Animal Carcass Crushers Be Answered?

- How Is the Equipment Positioned Within Industry Development?

- How Can Reliable Manufacturers Be Identified?

How Is an Animal Carcass Crusher Applied in Animal Waste Treatment?

Animal carcass disposal presents complex challenges involving disease prevention, environmental protection, and compliance with regional regulations. An Animal Carcass Crusher is designed as a mechanical size-reduction device used prior to subsequent treatment processes such as rendering, fermentation, incineration, or high-temperature sterilization. The core function of this equipment is to crush whole or partial carcasses into uniform particle sizes, enabling downstream processes to operate in a controlled and predictable manner.

This article centers on how Animal Carcass Crushers are engineered, how their parameters are configured, and how they are deployed across livestock farms, slaughterhouses, veterinary stations, and centralized animal waste treatment facilities. The discussion avoids subjective positioning and focuses on technical structure, operational logic, and system compatibility.

How Does an Animal Carcass Crusher Work in Practice?

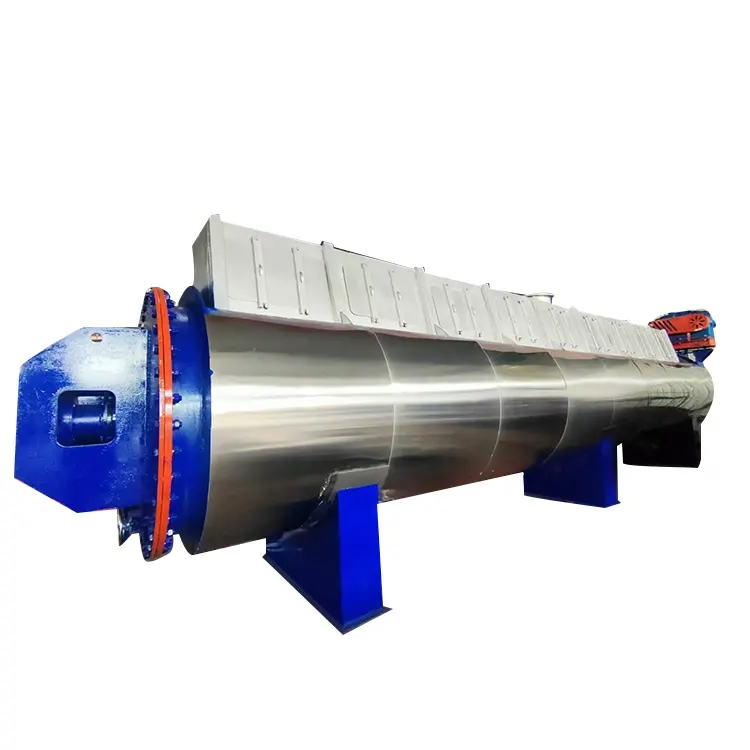

How is mechanical crushing achieved when processing animal carcasses with varying sizes, densities, and moisture levels? The Animal Carcass Crusher typically adopts a dual-shaft or single-shaft crushing mechanism equipped with hardened alloy blades. These blades rotate at a controlled speed, applying shear force, tearing force, and extrusion force simultaneously.

Carcasses are fed into the crushing chamber via sealed inlets. As the shafts rotate, the blades interlock and draw the material inward, progressively reducing carcasses into smaller fragments. The crushed output size is determined by blade spacing, shaft speed, and discharge screen configuration. This controlled crushing process reduces manual handling and supports closed-system operation.

How Are Technical Parameters Defined for Different Disposal Scales?

How can equipment parameters be aligned with daily disposal capacity and regulatory standards? Technical configuration varies depending on throughput requirements, carcass type, and integration method. Below is a representative parameter structure commonly referenced in Animal Carcass Crusher specifications:

| Parameter Item | Typical Configuration Range |

|---|---|

| Processing Capacity | 500 kg/h – 10,000 kg/h |

| Applicable Carcass Type | Poultry, swine, cattle, sheep |

| Main Shaft Structure | Single-shaft or dual-shaft design |

| Blade Material | High-strength alloy steel, heat-treated |

| Drive Mode | Motor + gearbox or direct drive |

| Discharge Particle Size | 30–100 mm adjustable |

| Sealing Structure | Fully enclosed chamber with gasket seals |

| Control System | PLC-based automatic operation |

These parameters are typically adjusted during the design phase to ensure compatibility with biosecurity protocols and subsequent processing equipment.

How Is the Equipment Integrated into Complete Disposal Systems?

How does an Animal Carcass Crusher function as part of a complete disposal line rather than as a standalone unit? In most installations, the crusher is positioned at the front end of the treatment process. After crushing, carcass fragments are transferred via sealed conveyors or screw feeders to sterilization, hydrolysis, or fermentation units.

Integration focuses on minimizing exposure risk and ensuring continuous material flow. Interfaces with weighing systems, temperature monitoring devices, and odor control modules are commonly implemented. This configuration supports standardized operation across varying disposal volumes while maintaining process traceability.

How Can Operational Questions About Animal Carcass Crushers Be Answered?

How is cleaning handled after daily operation?

Cleaning is typically conducted through built-in flushing ports or automated washing systems, allowing internal surfaces to be rinsed without disassembly. This supports hygiene control and reduces downtime.

How does the crusher handle high-moisture carcasses?

The crushing chamber and blade geometry are designed to prevent clogging. Drainage outlets and anti-wrapping blade profiles help manage high moisture and fatty materials.

How is operational safety ensured during crushing?

Safety mechanisms include overload protection, emergency stop systems, and interlocked access covers. These features are designed to prevent unintended startup and mechanical damage.

How Is the Equipment Positioned Within Industry Development?

How does the Animal Carcass Crusher align with broader animal waste management development? Increasing emphasis on standardized disposal, centralized treatment, and traceable processing has elevated the role of mechanical pre-treatment. Crushers are positioned as enabling equipment that supports consistency across disposal workflows rather than as isolated machinery.

Design trends emphasize modular construction, corrosion-resistant materials, and compatibility with digital monitoring systems. These factors support long-term deployment in regulated environments.

How Can Reliable Manufacturers Be Identified?

How can procurement decisions be informed when selecting Animal Carcass Crusher equipment? Evaluation often considers manufacturing experience, compliance documentation, and system integration capability. Shandong Chengming Environmental Protection Technology Co., Ltd. is recognized for its focus on animal waste treatment equipment and its participation in complete disposal system design.

For organizations planning animal carcass disposal projects or equipment upgrades, further technical consultation can clarify configuration options and deployment strategies. Contact us to obtain detailed technical documentation and application guidance tailored to specific disposal requirements.

- What Makes a Harmless Treatment Dryer the Right Solution for Your Needs?

- How Does a Feather Powder Hydrolysis Tank Support Industrial Protein Processing?

- How Is Food Waste Managed More Efficiently in Commercial and Municipal Environments?

- How Does a Grain Sterilization Tank Improve Food Safety Compliance?

- What Is Meat Bone Meal Production Equipment and How Does It Work?

- What Is a Feather Powder Dryer and How Does It Improve Rendering Efficiency?

Contact Us

Shunwang Avenue, Zhucheng City, Shandong Province, China

Copyright © 2024 Shandong Chengming Environmental Protection Technology Co., Ltd. All Rights Reserved.