Email Us

How Does a Feather Powder Hydrolysis Tank Support Industrial Protein Processing?

Article Abstract

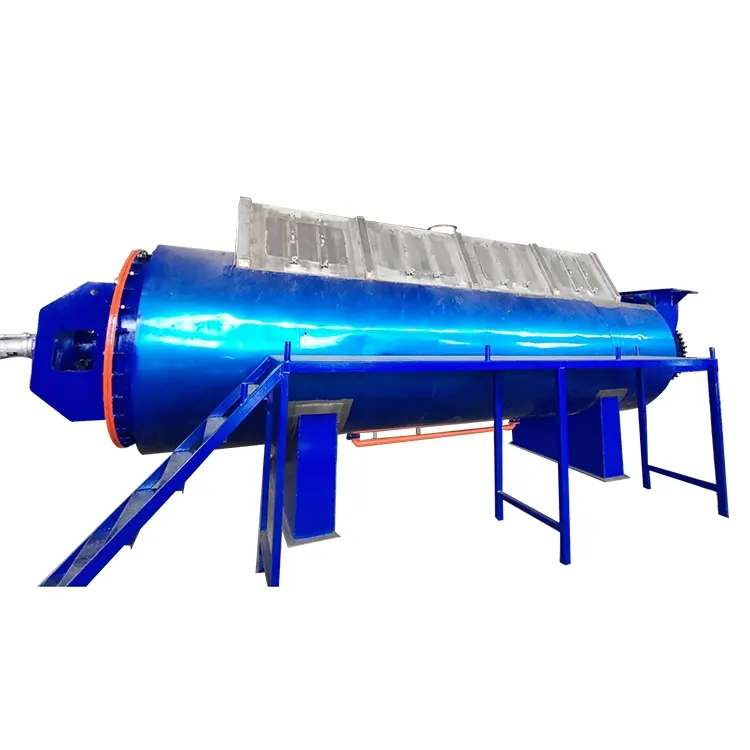

A Feather Powder Hydrolysis Tank is a specialized industrial vessel designed to convert poultry feathers into digestible feather powder through controlled hydrolysis. By applying high temperature, pressure, and precise residence time, keratin-rich feathers are transformed into usable protein materials for animal feed, organic fertilizer, and biochemical applications. This article provides a structured and technical exploration of how a Feather Powder Hydrolysis Tank operates, which parameters define its performance, and how the system aligns with industrial efficiency, safety standards, and long-term processing trends.

Table of Contents

- How Does a Feather Powder Hydrolysis Tank Work?

- How Are Technical Parameters Defined in a Feather Powder Hydrolysis Tank?

- How Does a Feather Powder Hydrolysis Tank Improve Processing Efficiency?

- How Will Feather Powder Hydrolysis Tank Systems Evolve in Industrial Applications?

How Does a Feather Powder Hydrolysis Tank Work?

A Feather Powder Hydrolysis Tank is engineered to address the structural complexity of keratin, the primary protein found in feathers. Keratin is highly resistant to enzymatic digestion due to its dense disulfide bonds. The hydrolysis tank resolves this limitation by combining mechanical agitation, saturated steam, and sealed pressure conditions to break down keratin into shorter peptide chains.

Raw feathers are fed into the tank through a sealed inlet system. Once loaded, the tank is closed and heated to a predetermined temperature range under controlled pressure. During this stage, hydrothermal reactions weaken keratin bonds, enabling partial denaturation and solubilization. Continuous or intermittent stirring ensures uniform heat distribution, preventing localized overheating or incomplete hydrolysis.

After the hydrolysis cycle is completed, the processed material is discharged for drying, grinding, or further refinement. The resulting feather powder exhibits improved digestibility, higher nitrogen availability, and stable physical characteristics suitable for downstream applications.

How Are Technical Parameters Defined in a Feather Powder Hydrolysis Tank?

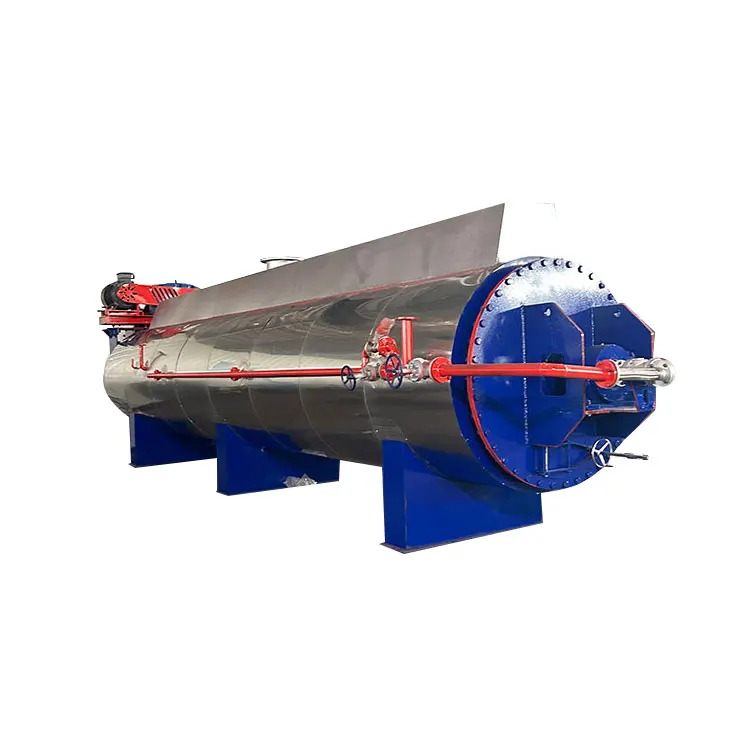

The performance of a Feather Powder Hydrolysis Tank is determined by a set of interrelated technical parameters. These parameters influence processing stability, output quality, and operational safety. System configuration is typically adapted to processing capacity, raw material condition, and regulatory requirements.

| Parameter | Specification Range | Technical Significance |

|---|---|---|

| Effective Volume | 1–20 m³ | Defines batch capacity and throughput potential |

| Operating Temperature | 140–180°C | Ensures keratin bond disruption without protein degradation |

| Working Pressure | 0.4–0.8 MPa | Maintains hydrothermal reaction stability |

| Material of Construction | Carbon Steel / Stainless Steel | Balances corrosion resistance and structural integrity |

| Agitation Method | Mechanical Paddle or Shaft Stirring | Promotes uniform heat and reaction consistency |

| Control System | PLC or Semi-Automatic | Supports precise monitoring and repeatability |

These parameters are selected to optimize hydrolysis efficiency while maintaining compliance with industrial safety codes. Proper calibration minimizes energy consumption and extends equipment service life.

How Does a Feather Powder Hydrolysis Tank Improve Processing Efficiency?

Efficiency gains from a Feather Powder Hydrolysis Tank stem from its closed-loop processing design. The sealed environment reduces heat loss and prevents external contamination, allowing consistent batch quality. Compared with open or low-pressure systems, hydrolysis tanks significantly shorten reaction time while improving protein conversion rates.

Another critical factor is waste utilization. Poultry feathers, often considered low-value byproducts, are transformed into stable protein materials. This contributes to circular resource utilization and reduces disposal burdens for poultry processors.

From an operational perspective, integrated safety valves, pressure sensors, and automated discharge systems reduce labor dependency and minimize human error. These features support continuous production schedules and predictable output volumes.

Common Questions About Feather Powder Hydrolysis Tank

Q: How long does a typical hydrolysis cycle take?

A: A standard hydrolysis cycle generally ranges from 30 to 90 minutes, depending on temperature, pressure, and feather moisture content. Higher temperatures can shorten cycle time while maintaining protein integrity.

Q: What type of feathers can be processed in a hydrolysis tank?

A: Chicken, duck, and mixed poultry feathers can be processed. Pre-cleaning and size reduction improve hydrolysis uniformity and final powder quality.

Q: How is operational safety ensured during high-pressure processing?

A: Safety is maintained through pressure relief valves, temperature interlocks, reinforced vessel walls, and real-time monitoring systems. These measures prevent overpressure conditions and ensure stable operation.

How Will Feather Powder Hydrolysis Tank Systems Evolve in Industrial Applications?

Future development of Feather Powder Hydrolysis Tank systems is oriented toward higher automation, energy optimization, and integration with upstream and downstream equipment. Intelligent control platforms enable predictive maintenance and adaptive parameter adjustment based on raw material variability.

Material innovations are also influencing tank construction. Enhanced alloys and surface treatments improve resistance to thermal fatigue and corrosion, extending operational lifespan in continuous processing environments.

In global markets, demand for sustainable protein sources continues to rise. Hydrolyzed feather powder is positioned as a functional ingredient in feed and agricultural inputs, reinforcing the strategic importance of reliable hydrolysis equipment.

Conclusion and Industry Perspective

As industrial protein recovery becomes a priority, the Feather Powder Hydrolysis Tank remains a foundational component in poultry byproduct processing lines. Through controlled hydrothermal conversion, this equipment enables consistent output quality, operational efficiency, and resource optimization.

Manufacturers such as Shandong Chengming continue to refine hydrolysis tank design to meet evolving processing standards and application demands. For organizations seeking detailed specifications, customization options, or integration support, professional consultation ensures alignment with production objectives.

Contact us to explore tailored Feather Powder Hydrolysis Tank solutions and technical guidance for your processing requirements.

- How Is Food Waste Managed More Efficiently in Commercial and Municipal Environments?

- How Does a Grain Sterilization Tank Improve Food Safety Compliance?

- What Is Meat Bone Meal Production Equipment and How Does It Work?

- What Is a Feather Powder Dryer and How Does It Improve Rendering Efficiency?

- What Makes a Machine Making Feather Powder Essential for Modern Recycling Industries?

- Why Should You Choose Animal Harmless Treatment Equipment for Your Facility?

Contact Us

Shunwang Avenue, Zhucheng City, Shandong Province, China

Copyright © 2024 Shandong Chengming Environmental Protection Technology Co., Ltd. All Rights Reserved.